A workshop vacuum, commonly referred to as a shop vac, is a specialized type of vacuum cleaner designed to handle tough cleaning tasks in workshops, garages, and construction sites. Unlike regular household vacuums, shop vacuums are robust and versatile enough to pick up both wet and dry materials. They can effortlessly handle sawdust, wood scraps, metal shavings, water, and other heavy debris which would normally damage standard vacuum cleaners.

Shop vacuums come in various capacities and power levels to suit different sizes of work areas and types of messes. Some models are equipped with large, durable tanks for holding debris, and they often feature stronger suction than household vacuums. With a host of attachments and extensions, they provide the flexibility to reach difficult spots and crevices. Certain models also offer portability with battery-powered options, making them convenient for use even where there is no immediate access to electrical outlets.

Understanding Workshop Vacuums

Workshop vacuums, often referred to as shop vacuums, are robust, versatile tools designed for the more demanding tasks that go beyond the capabilities of regular vacuum cleaners. They excel in a variety of environments, from DIY project areas to professional job sites.

Definition and Purposes of a Workshop Vacuum

A workshop vacuum, also known as a shop vacuum or wet/dry vacuum, is a specialized form of a vacuum cleaner that is capable of handling heavy-duty cleaning tasks. It’s designed to collect both wet and dry materials, making it a versatile addition to any workshop or construction site. These devices can suck up everything from fine dust particles to larger debris, such as wood chips or metal shards. Moreover, unlike regular household vacuums, many of these units can also manage liquid spills.

- Main uses:

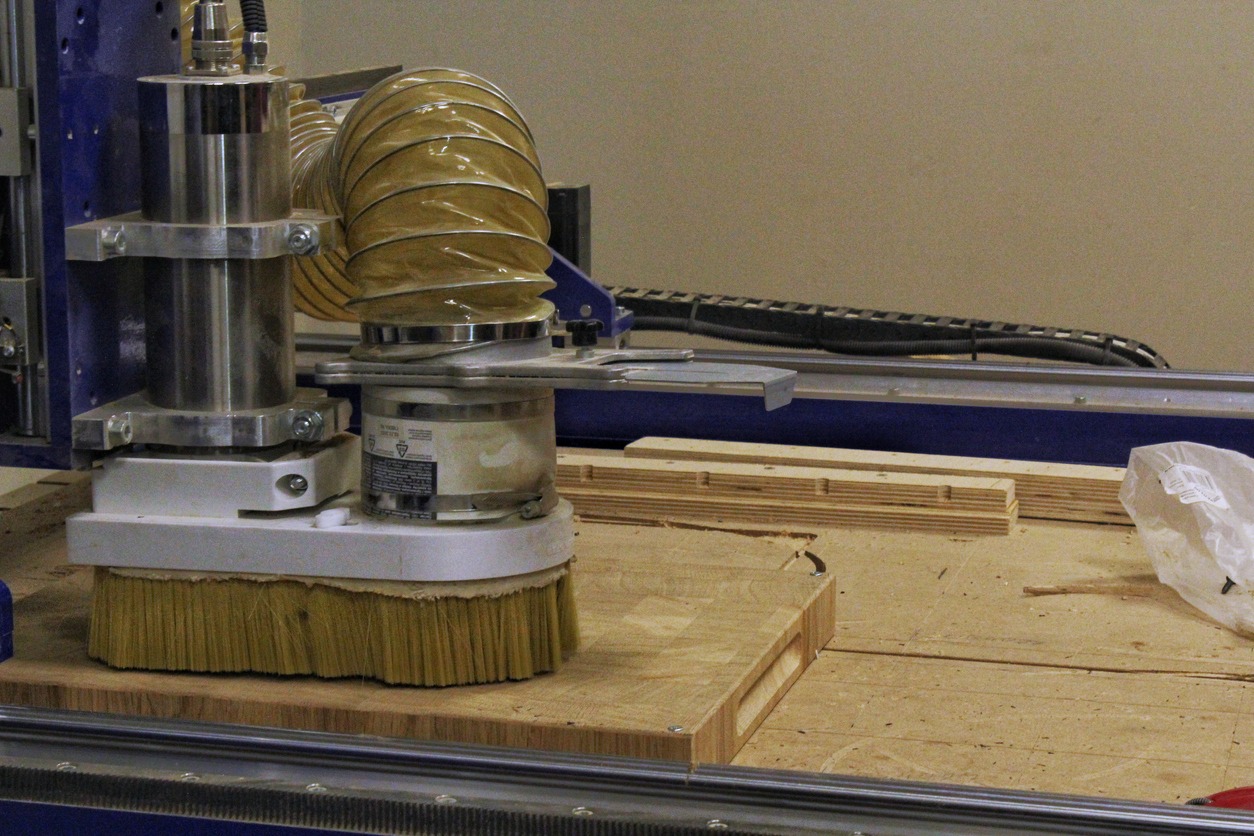

- Picking up sawdust and debris from power tools

- Cleaning liquid spills or water

- Unblocking drains

- Collecting broken glass or larger waste

Comparison With Regular Vacuum Cleaners

When compared to regular vacuum cleaners, workshop vacuums are engineered for durability and power. Regular vacuums are designed primarily for cleaning dust, dirt, and smaller debris from household surfaces such as carpets and floors. In contrast, workshop vacuums come with:

- Enhanced Features:

- Durability: They typically have crush-resistant hoses and sturdy, larger-capacity tanks.

- Power: Higher horsepower to manage tougher tasks.

- Mobility: Often equipped with wheels or carrying handles for easier transport.

- Capacity: Larger tanks mean less frequent emptying and potentially less maintenance.

In essence, a workshop vacuum serves as the bulwark for cleaning vast arrays of messes and debris that would otherwise damage or clog a regular vacuum cleaner.

Types of Workshop Vacuums

Workshop vacuums come in various forms to accommodate different cleanup needs, ranging from liquid spills to fine dust. They are designed to be more robust and versatile than regular household vacuums, often featuring larger capacities and stronger suction.

Wet/Dry Shop Vacuums

The Wet/Dry Shop Vacuum is the most versatile type, capable of handling both liquid spills and solid debris effortlessly. These vacuums typically range in size from 6-gallon to 10-gallon tanks and include powerful suction capabilities measured in cubic feet per minute (CFM). Users can easily switch between wet and dry modes, making them indispensable in workshops where a variety of materials are used.

Wall-Mounted Vacuums

Wall-Mounted Vacuums save on floor space with a permanent fixture on the wall. Their compact design optimizes workshop organization and they often come with a long hose to reach around the work area. These models can be very powerful and are ideal for small to medium-sized workshops where floor space is valuable.

Portable and Handheld Models

For ease of movement and convenience, Portable and Handheld Models are ideal. They offer significant portability and can often be operated through a cordless design, powered by a cordless drill battery for quick cleanups. These compact units are perfect for tasks that require mobility, such as cleaning vehicles or on-the-go job sites.

Key Features to Consider

When selecting a workshop vacuum, consumers should prioritize characteristics that match their specific needs for performance and convenience. Each feature plays a significant role in the vacuum’s overall functionality and suitability for various tasks.

Suction Power and Motor

The vacuum’s motor dictates its suction power, which is critical for efficient debris collection. Motors are rated in horsepower (HP), with higher HP offering greater power. Consumers should look for vacuums that provide a balance of power and efficiency relevant to their work environment.

Tank Size and Material

Tank size is measured in gallons and determines how much debris the vacuum can hold. A stainless steel tank is a durable option, combining longevity with ease of cleaning. Larger tanks require less frequent emptying but are heavier, which could impact maneuverability.

Filter Types

Filters are central to a vacuum’s performance, especially when dealing with fine particles. A HEPA filter is recommended for the best filtration, capable of trapping 99.97% of dust as small as 0.3 microns. Users should check if the vacuum accommodates wet, dry, or both types of debris.

Noise Level and Sound Design

Vacuums can be loud, so checking the noise level, measured in decibels (dB), is vital for a more comfortable work environment. Models designed with sound-dampening materials or techniques can significantly reduce noise, minimizing disruption in shared spaces.

Design and Operation

The design and operation of a workshop vacuum are critical for its efficiency and user-friendliness. Details such as hoses, storage, and ease of operation must be meticulously curated to match the power, like that of a 5 horsepower motor, with functional usability.

Hoses and Attachments

A workshop vacuum typically uses hoses of varying diameters and lengths to accommodate different types of debris and workspaces. Nozzles should be interchangeable and come in shapes suited for narrow crevices or wide areas. For instance, a Ridgid workshop vacuum might offer a robust hose capable of withstanding rigorous use, maximizing the power delivered by its 5 horsepower motor.

Storage Solutions

Storage is crucial for housing the vacuum hoses, nozzles, and other attachments. Securing these components often involves builtin storage compartments with latches for compact and safekeeping. Users value designs that consider easy access to all parts, preferably within arm’s reach to avoid interruption of work.

Ease of Operation

Workshop vacuums are optimized for easy operation, with features designed to turn on and off without hassle. They should possess clear, simple controls, perhaps with a one-touch operation that does not require bending or reaching awkwardly to initiate power. Features that consider user comfort and efficiency, aligning with the potent cleaning offered by something like a 5 horsepower motor, are always at the forefront of design considerations.

Maintenance and Care

Proper maintenance and care are foundational to the functionality and longevity of a workshop vacuum. These practices ensure that the vacuum performs optimally in handling both wet and dry debris.

Cleaning and Filter Replacement

Regular cleaning of the workshop vacuum is crucial to its performance. It’s important to empty the dust canister after use and wipe down the exterior to prevent buildup. Filter care is equally essential; filters should be replaced or cleaned depending on the manufacturer’s recommendations. For example, a HEPA filter might require replacement after a certain period, while a washable filter can be cleaned and reused.

- Cleaning steps:

- Turn off and unplug the vacuum.

- Remove and empty the canister.

- Clean or replace the filter.

- Wipe down the vacuum’s exterior.

- Filter care:

- Check for damage or wear.

- Replace disposable filters regularly.

- Wash and dry reusable filters according to the instructions.

Dealing With Wet and Dry Debris

Workshop vacuums are designed to tackle both wet and dry debris, which necessitates different maintenance approaches. Always use the appropriate filter for the type of debris. For dry debris, a standard filter suffices, but a wet filter is necessary for moisture-heavy cleanup to prevent damage to the vacuum’s motor and internal components.

- Guidelines for handling debris:

- Use a bag for fine, dry dust to protect the filter.

- Opt for a foam sleeve when dealing with liquids.

- Switch to the correct filter before changing the type of debris cleanup.

Storage and Longevity

The way a workshop vacuum is stored impacts its durability and readiness for the next use. It should be stored in a cool, dry place and fully disconnect from power when not in use. Regularly inspecting the hose and attachments for blockages or damage and addressing these issues promptly will also enhance the vacuum’s longevity.

- Storage tips:

- Ensure the vacuum is clean and dry before storing.

- Coil the power cord loosely to prevent damage.

- Store attachments in a designated place to keep them accessible.

By adhering to these specific maintenance and care practices, one prolongs the life of a workshop vacuum and ensures it is always ready for efficient cleanup of various debris types.

Popular Workshop Vacuum Brands and Models

Selecting a workshop vacuum involves choosing from reputable brands known for reliability and performance in cleaning up tough messes. Here’s a look at some popular models from leading manufacturers.

Dewalt Poly Wet/Dry Vac

The Dewalt Poly Wet/Dry Vac is renowned for its high efficiency in both wet and dry environments. Its robust design accommodates medium-sized jobs making it a versatile option for many workshops.

Craftsman Wet/Dry Vac

Craftsman Wet/Dry Vac is distinguished for being particularly heavy-duty. It boasts a strong suction power and is priced competitively, offering value for those who need a reliable vacuum for regular, intense use.

Ridgid 12-Gallon Shop Vac

For larger messes, the Ridgid 12-Gallon Shop Vac stands out. It has a substantial capacity and is equipped with a powerful motor, designed to handle big clean-up tasks with ease.

Stanley Shop Vac

The Stanley Shop Vac offers an excellent balance of durability and portability. Stanley is a trusted name for many tool users, and their shop vacs are no exception, with reliable performance across a range of models.

Ryobi 40V Vacuum

For those in need of a battery-powered solution, the Ryobi 40V Vacuum is a leading choice. It provides the convenience of cordless operation without compromising on the suction needed for workshop clean-ups.

Choosing the Right Workshop Vacuum for Your Needs

When selecting a workshop vacuum, key factors like the workshop size, the types of debris, and the budget play critical roles. This selection process ensures a clean, efficient, and value-conscious workshop environment.

Assessing Your Workshop Requirements

Identifying the primary use of your workshop vacuum is crucial. For general debris such as sawdust or leaves, a standard shop vac may suffice. A wet/dry shop vacuum is essential if you need to tackle spills or collect liquids. The size of the workshop influences the choice as well; larger spaces may require vacuums with more extensive reach and capacity.

- Type of debris: Dust, leaves, liquids

- Space size: Small, medium, large

Considering Budget and Value

Workshop vacuums come at various price points, and determining what you’re willing to spend beforehand is wise. While it may be tempting to opt for the cheapest model, consider longevity and efficiency. It’s often cost-effective to invest in a durable vacuum that won’t require frequent bag replacements or has a more robust motor capable of handling diverse cleaning tasks.

- Price range: Inexpensive, mid-range, high-end

- Long-term value: Durability, maintenance costs

Evaluating Mobility and Design Features

The design of a workshop vacuum can impact its usability. For larger workshops, a vacuum on wheels offers greater mobility and convenience. Compact designs serve smaller spaces well and minimize storage issues. Features such as adjustable suction, filter types, and accessory availability also play a role in how the vacuum will perform in the workshop.

- Mobility considerations: Wheeled designs, lightweight models

- Design features: Adjustable suction, accessory options

Accessories and Upgrades

Enhancing the functionality of a workshop vacuum often involves adding accessories or making upgrades. These enhancements can range from finer filtration systems to specialized attachments designed for specific tasks.

Additional Filters and Bags

Filters: Choosing a HEPA filter is critical for trapping fine dust particles, minimizing health risks from airborne particulates.

Bags: It’s essential to select the appropriate sizes and types of collection bags that match with one’s vacuum model for optimized performance and maintenance.

Specialized Nozzles and Tools

Nozzles: A range of nozzles, such as a crevice tool, allows for cleaning in tight spaces and corners, making the vacuum more versatile.

Tools: Some models offer a blower function or a built-in blower port for added versatility, enabling the vacuum to clear debris in addition to suction tasks.

Upgrade Kits and Compatibility

Upgrade Kits: Many manufacturers provide kits to update older models with newer features or improved functionality.

Compatibility: When choosing accessories or upgrade kits, ensuring compatibility with the existing vacuum unit is essential for proper function.

Safety and Best Practices

Workshop vacuums are essential in maintaining a clean and safe work environment, especially in areas where sawdust and debris are common by-products. Proper use and adherence to safety best practices can enhance the functionality and lifespan of these machines.

Proper Use and Safety Measures

Workshop vacuums are designed to handle tough debris like sawdust and small pieces of waste from power tools. To ensure safety and efficiency:

- Always check the vacuum’s power cord for damage before use to prevent electrical hazards.

- The vacuum should only be operated with the correct filters installed to manage fine particulate like sawdust and protect the motor.

- Regularly empty the vacuum to maintain optimal suction and prevent overheating.

- Users should avoid vacuuming wet materials unless the vacuum is specifically designed for wet and dry waste to prevent electrical risks and damage to the device.

Avoiding Common Mistakes

Certain practices can decrease the effectiveness of a workshop vacuum and pose safety risks:

- Do not use a workshop vacuum to blow debris away, unless it is designed for this function, as it can cause dust to become airborne and create a health hazard.

- Never bypass safety features or remove guards that are in place to protect the user from moving parts or electrical components.

- Avoid using the vacuum for substances it is not rated to handle, such as flammable or hazardous materials, which could cause injury or damage the equipment.

By following these specific guidelines, users can ensure a safer work environment and the reliable operation of their workshop vacuums.

Frequently Asked Questions

Selecting the right workshop vacuum depends on specific needs and understanding the varied applications of these tools. This section covers some common questions to help you make an informed decision.

How do I determine the necessary size for a shop vacuum?

The size of the shop vacuum needed often correlates with the volume of debris it will need to handle. Consider the capacity of the drum and how often you expect to empty the vacuum. Larger capacities are suitable for heavy-duty usage, while smaller ones may suffice for light, infrequent cleanups.

What are the primary uses for a workshop vacuum?

Workshop vacuums are designed to handle tough cleaning jobs. They typically collect wood shavings, metal filings, dust, and liquid spills in various workshop environments. They are also utilized for dust collection from power tools to maintain a clean workspace and reduce health risks.

In what ways do wet/dry vacuums differ from standard vacuums?

Wet/dry vacuums, often known as shop vacuums, can clean up both liquids and dry materials, unlike standard vacuums that are designed solely for dry debris. Their robust construction allows them to withstand the rigors of a workshop or construction site.

What should I consider when choosing the best shop vacuum?

When choosing a shop vacuum, consider factors such as suction power, filter efficiency, drum capacity, portability, and noise level. Additionally, evaluate whether the vacuum is compatible with dust collection systems for tools and the range of accessories available.

What accessories are essential for a wet/dry workshop vacuum?

Important accessories for wet/dry vacuums include hoses with different diameters for various tasks, extension wands for extended reach, various nozzles for precision cleaning, and brushes for delicate surfaces. HEPA filters may also be necessary for trapping fine particles.

How does a commercial vacuum differ from a workshop-specific vacuum model?

Commercial vacuums are generally built for frequent use in various environments like offices or retail spaces and may not have the same robust design as workshop vacuums. Workshop vacuums are tailored to deal with larger and potentially hazardous debris and can be part of a more comprehensive dust collection system.