As woodworkers place demands on their material that nature never intended, joint making is necessary. An interconnected network of fibers connects a branch to the tree trunk. when a table’s leg is fastened at a sharp 90-degree angle. Therefore, even if a well bonded connection is more durable than wood fiber, the stresses applied to tables, chairs, cabinets, and doors during regular usage are typically too great for that bond to support.

The majority of joints require some type of mechanical assistance, such as a reinforcement built to withstand loads. The joinery craft was born out of this requirement. The art and science of joinery, the building blocks of carpentry, are subtly combined. The joinery will determine the product’s value, whether it be a straightforward tabletop or an elaborate chest: Strong joints will ensure its life, and its design and craftsmanship will increase its attractiveness.

Basic types of wood joints

Wood joints provide a considerably more aesthetically pleasing and stable way to link two pieces of wood together than nails or screws do. They are utilized in fixtures and furniture that are present in homes. When making furniture, joints are utilized to keep the wood from splitting, which is crucial if the piece will be used frequently. Fine furniture joints, whether machine-made or by hand, create the impression that the item was constructed by a more costly artisan.

There are several common types of joints, and each has a distinct function. While some are simpler to construct than others, all call for a high level of carpentry expertise.

Butt joint

Although the most straightforward to construct, the butt joint is also among the weakest. It is an easy-to-use wood joint that is used in a range of woodworking tasks, such as raised garden beds and furniture.

By aligning the wood equally, attach the end grain of one piece of wood with the long grain of another at a straight angle. The components can be glued together, and the junction can subsequently be strengthened with screws or nails. Drive your nails through the grain of one board by hammering them into its face.

Dowels are also useful for butt joints; simply use a dowel jig to drill the appropriate holes into the wood pieces, then glue the dowels in place.

Mitred butt joint

An angled corner is made by mitering one or both ends of two boards to a 45-degree angle rather than joining them at a 90-degree angle with a mitered butt joint. After that, you may use screws or nails to secure the boards together. This kind of joinery is utilized in exposed beam applications.

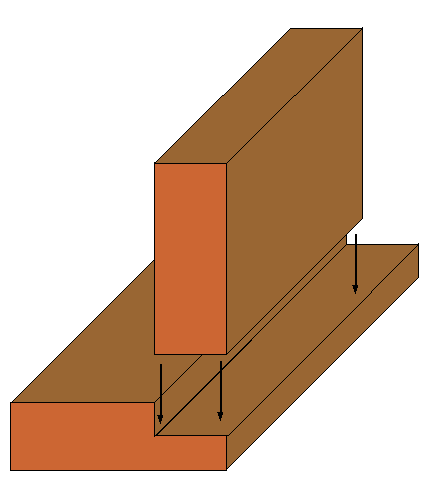

Dado joint

With this kind of joinery, one piece of wood has a single groove carved into its surface so that the second piece will fit precisely inside the slot. Cut the gap perpendicular to the wood grain if you must. The dado slot has two options: it can continue to the opposite end of the wood board or it can stop short of the edge.

Dado joints are often utilized in drawers, cabinets, and bookshelves. The dado joint, which joins the bookshelf or other piece of furniture’s side and back, is where you would use it.

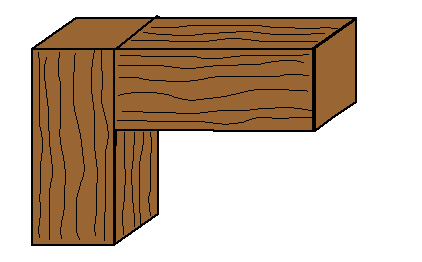

Rabbet Joints

Essentially a little lap joint that is mostly seen on longitudinal edges. In a rabbet joint, one piece of wood is given a groove or recess (rabbet) along its edge so that the other piece may fit into it perfectly. In addition to offering more strength and stability than the butt joint, this joint offers a superior gluing surface. In cabinetmaking, drawer building, and other uses where extra strength is needed, rabbet joints are frequently employed. Rabbets prevent a continuous gap from being formed when the wood contracts and expands. Wood wall panels and flooring are two examples of straightforward rabbet joins.

Mortise and tenon joint

One of the oldest styles of woodworking joints is this one. It includes a mortise, which is a hole or hollow cut into the side of one board in the shape of a rectangle or square, and a tenon. The tenon, which is the same size as the mortise, is an outgrowth on the opposite board.

The tenon should, in general, be around one-third the thickness of the wood. Although you must make sure the mortise and tenon are the proper sizes to ensure a precise fit, once it is in place, this sort of woodworking joinery looks exquisite because no nails or screws are required.

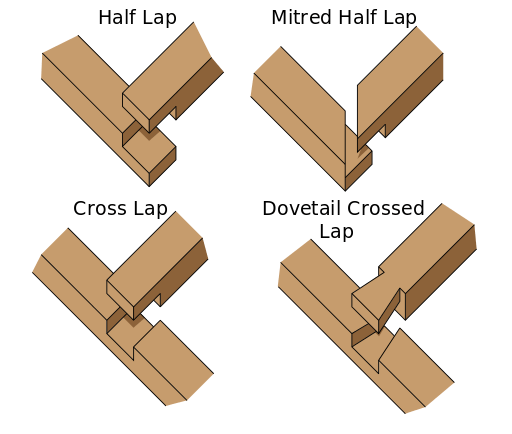

Half lap joint

Half of each piece of wood’s thickness is eliminated during a half lap wood joint. The boards should fit together perfectly like a puzzle piece of wood once you glue them together. When the wood pieces you’re utilizing are the same thickness, this is an excellent joint to employ. You may construct desks or storage furniture using lap joints.

Other forms of lap joints include:

- Mitred lap– Mitred edges (45-degree angled edges) can be cut on both pieces of wood. This is the weakest lap joint even though it is useful for forming corners.

- Cross lap– This type of connection, which may be used for interior cabinet frames. The joint is created in the center of one or both pieces of wood.

- Dovetail crossed lap – A trapezoid form is made by cutting the housing slot and attaching stem piece with two angled edges. Because of the increased difficulty in removing the stem from the housing, a stronger grip is achieved.

Tongue and groove joint

This kind of wood joint features a grooved notch on one board’s edge that continues over the board’s edge. The connecting board’s edge then has an expanded, narrow tongue that fits within the housing board’s groove. The boards lock into place once they have been assembled. Laminate flooring and floating wood flooring are two common applications for this kind of connection.

Transition to advanced techniques

Certain joinery techniques, which may offer greater strength, more visual appeal, and more marks in a large project, are never employed because they require a bit more work than others or because they are perceived as “challenging.” Woodworkers can advance to these wood joinery techniques:

Butterfly Joints

The butterfly key joint, often called a double dovetail joint, strengthens expanding junctions by increasing the surface area of the joint. The key undoubtedly provides a decorative feature if it is cut to a contrasting wood.

There are a few different ways to create this connection, but the simplest is to use a table saw to cut the “key” and a suitable router piece to cut the recesses for the keys.

Spline Joints

Although a spline joint is an addition to conventional joints, it is not necessarily a joint in and of itself. A spline doesn’t take much longer or need much more effort, but it gives a joint more strength since it has more surface area. When used contrasting wood, it may also add another design aspect to the project.

Dovetail Joints

One of the most recognizable joints and a mark of skilled workmanship is the dovetail joint. They are composed of a sequence of trapezoidal-shaped tails and interlocking pins. Although veneers concealed them for a long time, they are now usually kept exposed to show off the artistry that went into making them.

They are most frequently employed in drawer construction because of their resistance to being pulled apart, which is their defining feature. It is simpler to make a box junction, which is a dovetail version without the trapezoidal form.

Biscuit Joint

Imagine biscuit joints as a butt joint that has been fortified. A piece of compressed wood, perhaps beech, makes up the biscuit. To attach the biscuit into both wood joints, you must use matching mortises. When using a biscuit joiner to make the mortises, precision is not required. The alignment and design of the joint are flexible until it is cemented together.

A fantastic contemporary woodworking joint is the biscuit joint. Biscuit joints work well when glue is used. Using planks to create tabletops is one example. The Beechwood biscuits line up and secure the joint. The Beechwood biscuits swell due to the premium adhesive, which holds the boards firmly in place. To save time cutting through wooden stocks, be sure to get a biscuit joiner.

Interlocking Tenon joint

A unique and uncommon joint is the interlocking tenon joint. It is made up of three timer components that join at a four-way junction. The two top pieces resemble a more complex cross halving joint, but they are really joined by a two-piece mortice that forms the four-pronged tenon. To make this joint precisely, it takes a high level of ability, a wide variety of tools, and plenty of time.

The design elements that can be seen at the end make this joinery design piece worth as much time it takes.

To make your working space, cleaner and healthier, here’s how: https://myhobbylife.com/make-your-working-environment-healthier-with-dust-collectors/

How Basic Wood Joinery Techniques Evolved into Advanced Methods

Wood has always been a common building material, which influenced the development of joinery techniques. Intricate joints were developed because of man’s intuitive approach and studies of how timber components behaved in stressful situations like earthquakes and natural catastrophes. These joints were like three-dimensional jigsaw puzzles, with every piece of wood precisely fitting to withstand stresses from nature and structure alike.

Modern building methods have made it less necessary to possess conventional joinery skills for woodcarving. As steel and less complex connections took the place of elaborate woodwork, standardized steel components that made assembly easier emerged. Nevertheless, the development of computer numerical control (CNC) technology continues to make it possible to produce faultless timber joinery.

The joinery industry has evolved into a more complicated one as hybrid constructions, which blend steel or concrete with mass wood, have become increasingly common. Because different materials perform differently mechanically and physically, connectors are required to respond to varied forces that collide with connecting elements and to increase the stiffness of the structure.

Two main types of connections are commonly seen in mass wood structures:

- Finger joints: These join pieces of wood together, forming laminated segments into unified wholes.

- Mechanical joints: They span a variety of custom and premade connectors and unite two mass wood parts. In this domain, engineering creativity is required for connection design, particularly for intricate arrangements like space trusses or trusses.

The progression from simple to complex joints

Making all these woodworking joints requires greater expertise. The advantage comes from greater reinforcing and increased durability as more complicated joins were created using classic and straightforward wood joinery procedures. The following are complicated, non-traditional woodworking joints that require specialist equipment when working on a project.

Pocket Hole Joints

Pocket hole joints are strong and take little time to make. It’s used for creating frame faces. It attaches wood with strong grain orientation such as table legs and aprons. Pocket hole joints are a great way to reinforce butt joints and can be hidden.

Screws in pocket hole joints are toe-nailed at an angle. These screws are more secure than for a butt joint wherein you place the screws in the end grain. Their woodworking joints help it hold in place and are more secure than other forms of wood joinery.

Box Joint

The box joint is both easy and difficult. Each incision is made at a perfect angle, making it straightforward. Because box joints call for several cuts to both pieces of wood, they are complicated. In essence, a box junction involves cutting a number of complementing, interlocking pieces into both sides of the wood and inserting them into one another to create a 90-degree corner. This joint is employed in our sector to create wooden chests, boxes, and drawers.

Dovetail joint

The dovetail joint’s inherent strength and aesthetic benefits make it a popular choice for advanced woodworking jobs. To fit the boards together, this style of joinery uses notches. When finished, the wood tails and pins have an interlaced appearance.

Consider the dovetail junction as the stronger, more reliable next step progression of the box joint. However, the cuts on a dovetail joint are tapered at an angle and wedge-shaped rather from being a sequence of straightforward, intersecting square or rectangular fingers. On one side, these parts are referred to as tails, and on the other, as pins. Even in the absence of fasteners, the dovetail joint’s angled incisions provide exceptional durability and security.

Dovetail joints are frequently used to create drawers and other box-like constructions, like the box joint. This junction has a nice appearance, and if it is constructed effectively, the ornamental element may be utilized to improve projects. The joint may be entirely buried in other projects. Making drawers is where the dovetail joint is used the most frequently.

The English and French dovetail joints are also two common varieties of dovetail joints. The simplest explanation is that French dovetails (also known as sliding dovetails) include a single long tail moved into position between pins, whereas English dovetails involve a succession of tails and pins repeated in a pattern.

Importance of mastering the basics

Wood joinery is essential to creating high-quality work because it enables the assembling of several pieces’ components into an aesthetically beautiful and structurally sound whole. Wood joinery techniques need perseverance and a lot of practice to perfect. Very sharp chisels and excellent hand-eye coordination will further strengthen the result.

It would definitely take time but eventually mastery over this requires both skill as well as creativity – in terms of choosing what style works best for each individual project.

Learning the craft of woodworking may be enjoyable. Not only are stunning and distinctive items produced, but also the crucial ability to produce robust joints. Any project involving woodworking must have wood joints since they form the framework of the building and provide it strength and stability.

Here are some fundamental abilities that must be developed for long-lasting and beautiful wood joinery:

Accurate measurements and mapping

Woodwork involves cutting wood into fine, even pieces. To be able to plan out the right length, breadth, and depth, measurements must be taken at every angle, whether it’s a wooden picture frame that fits exactly or a dining table with precise height requirements.

Accurate measuring is essential to creating a product that is both structurally sound and visually appealing. It just requires experience and effective marketing and measuring tools, all of which are readily accessible on the market.

Cutting straight pieces

Making basic and sophisticated cuts can be made by mastery of skills. However, making straight cuts, could even be more challenging. These are the kinds of abilities that are immediately covered in entry-level woodworking to help one become solid and obstinate while handling large pieces of wood.

There are several different instruments on the market, including handsaws, miter saws, and power saws. The straight, clean cuts are practically attainable with these equipment. You can cut precisely by learning how to utilize them to get straighter slices.

Wood drilling

This may seem like a simple talent for a novice to learn, but a beginner will find it difficult to handle the weight of the drilling machine and drill even little holes. Drilling holes of various sizes and depths may be required depending on the project.

Woodworkers with proper training can drill holes while avoiding flaws and inconsistencies. So, before you think of making a chair or a bookcase for your home, be sure to master the fundamentals of drilling.

Using cutting saws

Saws come in a variety of sizes and shapes, and even those who like doing things on their own can find heavy jobs easy and doable with a little practice. Saws are good for both pruning and lumbering.

To become an expert, one must begin practicing. Use a circular saw for lengthy cuts; jigsaws are better for creating complicated curves and patterns.

Hammering nails

Hammering nails is a talent that is surprisingly undervalued. Who wouldn’t need to know how to drive a nail, after all? This is a fundamental ability that must be perfected to produce an effective result and reliable assistance.

Familiarity with angles and joinery

If there is anything other than dimensions that may detract from the accuracy and appearance of wooden works of art and make them appear entirely out of place, it is a lack of knowledge and comprehension of angles and joinery. Thorough awareness of the delicate and crucial ability of cutting compound angles with perfect joinery is totally needed.

Curating wooden pieces that are well-balanced and well aligned in sequence requires maintaining suitable angles. They are not only robust enough to stand the test of time and have an appealing appearance.