Power tools are among the most time-saving devices ever invented. Through the use of combustion, compressed air, or electricity, they enable us to finish tasks that others using traditional tools either could not accomplish or would take lots of time to complete. They can also be divided into many categories, such as portability, power source, and purpose.

Most of the time, power tools come in one of two categories, either stationary or portable. Stationary power tools are either large machines that can’t be moved easily or those that need to be fastened tightly to a stationary object to function properly. Portable power tools, on the other hand, can be carried easily from one place to another. They are mostly light enough to be used while being held in the hands.

Another way to categorize power tools is through the energy that they utilize to function. As mentioned earlier, power tools usually run on one of three types of power which are combustion, compressed air, or electricity. When compressed air is utilized, the air is pushed through the tool in order to move different mechanical parts. Air compressors are mostly powered by electricity or a combustion engine. Power tools that are powered by electricity most often use electric motors. This means that they need to be plugged into an electrical outlet or powered by a battery. Lastly, power tools that are powered by combustion use small explosive charges called cartridges or combustion engines.

If you want to learn more about the various power tools available and how they are used, you’re in the right place. In this post, we’re giving you an infographic on the different types of power tools.

Power Drills

Drills are toolbox essentials for home improvers and trade professionals alike. They are used to bore holes, loosen, or tighten screws, as well as chisel away materials. Power drills can also be used on different surfaces and materials. There are different types of drills available in the market. Some of them are corded, and others are cordless.

Corded power drills are usually lighter compared to cordless ones as they do not have a heavy battery pack. However, you will need to use an extension lead if you opt for a mains-powered, corded drill. A cordless drill, on the other hand, can provide greater mobility as it can be carried anywhere without having to tow an extension cable behind you. However, they are usually more expensive than corded power drills.

Below are the different types of power drills:

- Power Screwdrivers

These are ideal for various screwdriver jobs around the house. Most power screwdrivers are cordless, which is perfect for tightening loose screws in tight spaces and for assembling flat-pack furniture quickly. These are handy little power tools that are lighter and more convenient to use compared to drill drivers. It also has forward and reverse settings, making it easier to use. However, note that power screwdrivers can’t drill holes.

- Drill Drivers

This is a perfect power drill if you are searching for a versatile tool that will handle small jobs around your home. Drill drivers not only drill holes into wood and metal, but they can also act as drivers, which can be used to tighten and loosen screws by using various drill and screwdriver bits. These are ideally used for putting up shelves, hanging pictures, and assembling flat-pack furniture.

- Combi Drills

This power drill offers all the same features as a drill driver, but it has the additional hammer-action feature. This makes it suitable for drilling into masonry and brick. These are 3-in-1 drills that are perfect all-rounder at home.

- Impact Driver

This is a heavy-duty screwdriver used for repetitive or larger screwdriver projects. It has an impact mechanism that helps reduce the impact on your wrist by doing more of the hard work for you. They are effective for tightening bolt heads and nuts and drilling into metal due to their high torque capacity. They are also a bit more compact and lightweight than a drill driver.

- Hammer Drill

This is a great power drill for drilling hard surfaces like concrete and masonry. It is perfect for heavy-duty tasks around the house, such as putting up shelves or securing gutters in place. It offers multiple torque settings to adjust the power while keeping the RPM low. This means that it can power through hard materials while limiting damage to the surface area at the same time.

- Breakers & Demolition Drills

This is made to handle breaking up hard materials such as blocks, bricks, concrete, and asphalt. These drills deliver more powerful blows to the surface. In addition to that, it can also be used to chisel channels in masonry and remove tiles.

Power Saws

Power saws are mechanical machines that are used for both DIY projects and industrial projects. This type of tool features blades, chains, wire, set of teeth, and more. It is basically used for the workpiece in large cuts. A power saw can cut wood, metals, plastic, concrete, and other materials such as bricks and tiles. Below are the different types of power saws and their uses:

- Circular Saw

This is a good all-around saw that you need to have in your power tool collection. It is used to make quick crosscuts or cuts across the woodgrain in dimensional lumber and rip-cuts or cuts along the woodgrain in sheet woods like plywood. It is great for projects like trimming wood fence posts to size or cutting decking boards. You can get a circular saw either in corded or cordless variations.

- Miter Saw

This type of power saw can make the same crosscuts that a circular saw can quickly. But its main feature is to create precise angled and beveled cuts. It is perfect for cutting molding or wood trim. It features a gauge on the saw table where you can set the saw to make accurate angle cuts. However, miter saws are not as portable as circular saws. But they offer a great level of precision and flexibility.

- Table Saw

A table saw can be used to cut boards to the right length or width quickly. But in addition to that, it is also perfect for cutting sheet materials like drywall or plywood. There is an adjustable fence on the table that is used as a guide for the workpiece, making it easy to make accurate, repetitive cuts with multiple pieces of wood. Different blades can also be used on a table saw. You need to ensure that you are matching the blade to the material that you are working on.

- Jigsaw

This is a versatile power tool that has a thin and narrow blade that is used to make straight, irregular, and curved cuts. Depending on its blade, it can cut through various materials, including metal, wood, and drywall. Its maneuverability and size will allow you to easily follow a pattern stenciled on a workpiece in cutting detailed designs. Also, with the right technique, you can use it to cut a circle in your workpiece. It can also be adjusted to make beveled cuts.

- Reciprocating Saw

This is a great tool to have for heavy-duty remodeling, such as cutting out a new window or drywall for switches. It is also sometimes used for demolition jobs where cutting through studs, pipes, and nails is needed. However, this type of saw does not cut as clean as some other saws. It has aggressive blades, and its reciprocating motion means it cuts very fast.

- Band Saw

This power saw has a flexible and continuous blade that runs around two wheels. Band saws that are larger and stationary are perfect for woodworking applications like cutting tenons, making curved cuts, and resawing. Portable ones, on the other hand, are great for job site tasks, such as making clean cuts in pipe and metal.

Power Sanders

Sanding your projects manually is a daunting task. Not only it is tedious, but the friction of the sandpaper against the work material can tire you out fast. Also, when uneven pressure is applied to the work material, the surface may end up with lines, gouges, and stroke marks. Therefore, to prevent this, the use of electric or power sanders is the way to go. Each task requires a different kind of sander. Here are the different types of power sanders:

- Random Orbital Sander

This is basically the most common type of electric sander that is found in stores today. It is also the most versatile among the different types. If you can only choose one sander to buy for your home projects, this is the best choice. It is the type of sander that prevents scuffing and scarring of the wood if you ever go against the grain. It is also easier to wield as its action is more like vibration. It is best used for fine projects, tables, chairs, or trim and baseboards where you need to pay attention to the surface condition.

- Belt Sander

This type of sander has a continuous loop of sandpaper, which is called a sanding belt. It runs through the machine, which is similar to the way the cutting chain runs through a chainsaw. It is perfect to be used for ripping off the rougher initial stages of any sanding project. It is best used for removing exterior paint, removing extraneous wood material, and hitting high spots on wood flooring.

- Rotary Sander

This is any sander, floor-mounted or handheld, whose head turns in circles. It enables you to get close to edges and is safe to be used on almost all materials. It can be used for sanding wood flooring right near the baseboards where other sanders could not reach. Rotary sanders can also be used for smoothing down trim to a mirror-like finish. However, note that it can get out of control and is best used by experienced DIYers.

- Drum Sander

This is a specialized belt-style floor sander that rests on the floor and is pushed via a handle, like a lawn mower. This type of power sander is a bit expensive for homeowners. They are mostly available for rent from rental centers. Also, keep in mind that it should be used for solid wood flooring only and not on engineered wood flooring or non-wood flooring. They are very powerful and can sand off all kinds of materials that you want to remove from a wood floor. These include mastic, paint, bumps, adhesives, stains, and gouges.

- Spindle Sander and Disk Sander

These power sanders are table-mounted and allow greater stability compared to handheld ones. On spindle sanders, the sandpaper is placed on a tube-like base. With disk sanders it is placed on a disk, which is commonly a table-mounted version of a handheld orbital sander. Both of these sanders are perfect for sanding down small items for woodworking projects.

Power Grinders

Power grinders are also among the most useful power tools, and they have been around for a very long time. Over the years, many different types of it have been developed. Each power grinder may look a bit different from another, even if they are the same type. They range from small handheld models to large industrial sizes. Below are the different types of power grinders:

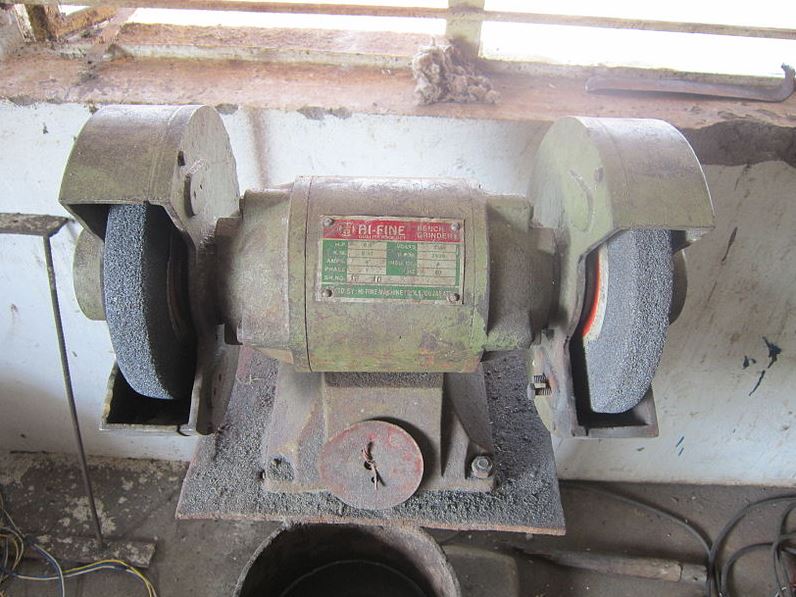

- Bench Grinder

This is a stationary power tool that is attached and bolted down to a workbench or table. It has two rotating abrasive wheels of various grain sizes for grinding down and shaping tools that are needed to be repaired or made. Buffing wheels or wire brushes can be interchanged with the grinding wheels to polish or clean workpieces.

- Die Grinder / Straight Grinder

This is a small handheld highspeed rotary tool that is used for shaping and polishing. It has a small diameter grinding bit. It can be used for grinding, sanding, honing, or polishing certain materials. It is available in both straight and right-angle heads. Most of them are powered by compressed air or by a small electric motor. There are also different attachments that can be used on a die grinder, such as for engraving, contouring, and woodworking.

- Right Angle Grinder

A right angle grinder or also known as an angle grinder, is the most common and popular type of power grinder. It also has a wide array of uses. It features a wheel at a right angle to the handle shaft of the tool. It is mostly used in construction and fabrication work. It is also a versatile tool that can be used with many kinds of attachments and cutters.

Woodworking Power Tools

Woodworking is one of the most common projects done at home by DIYers. Therefore, you also need to have the right power tools for these tasks to be able to complete your projects successfully. Here are some of the most useful woodworking power tools that you must have:

- Drill Press

This is a type of power tool that drills small holes and bores big ones. It also gives you the option to set the depth accurately. The table of this tool also adjusts for angled drilling. It uses a multiple-cutting-edged drill bit that is secured in a rotating chuck to bore and drill holes commonly into wood stock.

- Router

A router routes or hollows out an area in a hard material, such as wood or plastic. It is most often used in woodworking, particularly cabinetry. It can either be fixed-base or the plunge type. A plunge router is more versatile as its up-and-down sliding motor housing allows workers to begin and end a cut in the middle of a board.

- Jointer

A power jointer is a tool used to flatten a face and edge of a rough board during the milling process. It has a long, flat, iron-cast bed that removes high spots progressively until the surface of the board is completely flat. It is also used to make the face of a warped, twisted, or bowed board flat.

- Planer

Just like a jointer, the power hand planer or electric planer has blades mounted on a cutter head or drum and spins at 20,000 rpm. It removes wood equal to the difference in elevation between the front and rear parts. Basically, it is used to even out wood to an exact thickness.

- Lathe

This is a power tool that rotates a workpiece about an axis of rotation to do different operations, such as sanding, cutting, deformation, drilling, and more, using tools that are applied to the workpiece to make an object with symmetry about that axis. It basically gives the rotary power to spin a piece of wood that you shape with a chisel.

Oscillating Multitool

An oscillating multitool is one of the best power tools that you can have. It is such a versatile tool that can handle many different projects and make your DIY projects much easier to finish. The secret behind its versatility is in the various tool blades that can be attached to it. Oscillating tool blades come in many different shapes, sizes, materials, and functions. Below are some of the best oscillating multitool blades:

- Fine Tooth Blades: These can be used to cut both wood and metal. They are mainly used for precise cuts to eliminate any guesswork on how deep you are cutting.

- Plunge Cut Blades: These blades provide a wider cut than fine tooth blades. If you have lots of materials to cut, such as paneling or drywall, using these blades can help speed up the process.

- Segment Saw Blades: These blades can cut anything from drywall to 2x4s and 4x4s. When you use this blade on an oscillating tool, you can start cutting the material without the need to start cutting from an edge.

- Scraper Blades: If you need to remove silicone, adhesive, old caulk, and more, using these blades is a great idea. It combines the versatility of the oscillating tool without the ability to cut. It will scrape away whatever you need to remove quickly.

- Sanding Pads: An oscillating tool can also double as a sander. However, it can only handle small sanding tasks like sanding off burs off of a newly cut board.

- Carbide Blades: These are durable blades used to remove grout or cut cement, brick, or concrete.

- Saw Blades: You can also use saw blades on an oscillating tool to cut drywall.

- Outlet Box Cutter: An oscillating multitool can also make cutting outlet boxes out of paneling or drywall easier with an outlet box cutter. With this blade, you no longer have to measure or mark on the wall. You just need to place the cutter where you want the outlet to be, ensure that it is level, and begin cutting.

Air Compressors

We have also included compressors or air compressors as they are some of the most necessary appliances at construction sites. Air compressors are used as a power source for some of the power tools mentioned here. They are categorized as either positive displacement or dynamic displacement.

Positive displacement compressors have various air compressors that generate power through air displacement. They work with different internal mechanisms, but all have the same principle. A hole inside the machine stores air brought from outside and slowly compresses the hole to increase the air pressure and potential energy. On the other hand, dynamic displacement compressors generate horsepower by bringing the air with fast rotating blades and then restricting the air to produce pressure. The kinetic energy is stored as static within the compressor. Below are some of the different types of air compressors:

- Rotary Screw Compressor

This is a common type of displacement compressor that is equipped with an internal cooling system. Most of them are big, industrial-sized machines that are either lubricated with oil or run oil-free. It has two internal rotors that turn in opposite directions where the machine generates energy. The air is trapped between these rotors and builds up pressure in the housing. Due to the internal cooling system, a rotary screw compressor is made for continuous use. It ranges from 5 horsepower up to 350 horsepower.

- Reciprocating Air Compressor

This is also an example of a displacement compressor. It is mostly used in smaller work sites like garages and home construction projects. Unlike the rotary screw compressor, this one is not designed for continuous use. It also has more moving parts, which are lubricated with oil for smoother movement. It works via a piston inside a cylinder, which compresses and displaces the air to create pressure.

- Centrifugal Compressor

This air compressor is dynamic. It slows and cools the incoming air through a diffuser to create potential energy. It can produce a high amount of energy in a relatively small machine due to the multi-phase compression process. It also requires less maintenance compared to the rotary screw and reciprocating air compressors. However, this air compressor is mostly used for more demanding construction sites, such as in steel manufacturing centers and chemical plants. This type of air compressor can reach up to 1,000 horsepower.

Conclusion

There are indeed lots of different types of power tools available today. All of these tools are useful and can help us work on and finish tasks and projects quickly and more efficiently. Therefore, if you are planning to improve your workshop soon by adding power tools to your collection, the ones we’ve mentioned here are all worth owning. Whether you are working on woodworking projects or home improvement projects, all of these power tools will surely come in handy. We hope this post helped you learn more about the different types of power tools.