Vise grips, commonly known as locking pliers, are a versatile tool in any craftsman’s toolbox. They function by a mechanism that allows them to lock around an object, thereby holding it firmly in place without continuous pressure from the user. The design of the vise grips provides an adjustable jaw which can be tailored to the size of the workpiece, ensuring a secure grip on a wide variety of objects.

The uses of vise grips are extensive and varied across multiple fields. They prove invaluable in situations where a traditional tool might falter, such as when a bolt is stripped or a screw is broken. Their strong gripping power allows them to serve as a temporary clamp, hold objects together for gluing, or even act as a handle for a damaged tool. They can also pinch a leaking pipe temporarily, offering a quick fix until permanent repairs are made.

These tools are simple to operate; by adjusting the screw located in the handle, the jaws can be opened to the desired width. Once positioned around the object, the user squeezes the handles together until the locking mechanism engages. Vise grips maintain their grasp without further intervention, letting the user focus on other aspects of the task at hand.

Understanding Vise Grips

Vise grips, also referred to as locking pliers, are versatile hand tools designed for gripping, clamping, and holding various objects securely. Their unique locking mechanism allows them to apply substantial force without requiring continuous grip strength from the user.

History and Development

William Petersen, a Danish blacksmith, invented the first vise grips in DeWitt, Nebraska, in 1924. In the United Kingdom, they are often called mole grips or mole wrenches, a term coined by Thomas Coughtrie of M. K. Mole and Son.

Components and Design

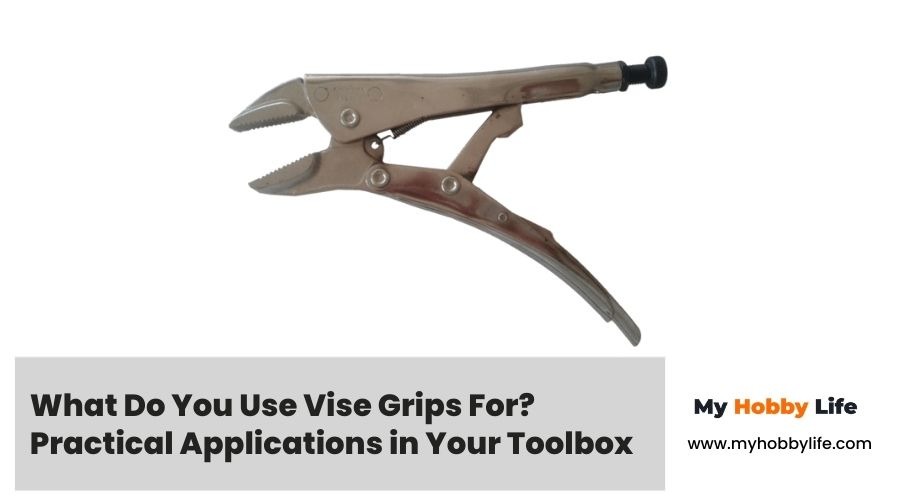

A typical vise grip includes handles, jaws, and a lever. The jaws may be serrated for better grip, and the design incorporates an adjustment bolt and a release lever. The locking feature is central, allowing vise grips to maintain a secure hold on items.

Mechanism of Action

The operation of vise grips involves a fulcrum, cam action, and clamping force. When the handles are squeezed, the mechanism actuates, applying force directly to the jaws, locking them onto the target item.

Types of Vise Grips

There are several types of vise grips:

- Curved-jaw locking pliers for rounded workpieces

- Long-nose locking pliers for precision and reach

- Straight-jaw for flat objects

- C-clamp vice grip for materials with flat sides

Material and Durability

Vise grips are typically made from high-grade metal such as chrome, which imparts durability and resistance to rust. The heavy-duty construction ensures they can withstand rigorous use.

Size and Form Variations

Vise grips come in different sizes to accommodate large objects and small objects. The capacity to grip various shapes is enhanced by the adjustment bolt, which varies the distance between the jaws.

Maintenance and Care

Maintain vise grips by regularly cleaning and applying penetrating oil for lubrication and rust prevention. Ensuring they are free of debris extends their lifespan and maintains efficiency.

Branding and Manufacturers

The original vise grips are associated with the Irwin brands, following William Petersen’s development of the tool. Irwin maintains a reputation for quality in the manufacture of various vise grips.

Practical Applications

A staple in many toolboxes, vise grips serve a multifaceted role:

- Gripping stubborn bolts or nuts

- Clamping parts for welding or cutting

- Holding objects securely in place

- Can function as temporary wrenches or pliers

Frequently Asked Questions

Vise-Grip pliers are a versatile tool used in various settings, from home DIY projects to professional trades. The following frequently asked questions address common uses and techniques associated with Vise-Grips.

How can Vise-Grip pliers be used in automotive repair?

In automotive repair, Vise-Grip pliers may be utilized to hold parts in place, grasp stubborn nuts or bolt heads, and provide leverage to turn stuck components. Their locking mechanism ensures a firm grip that assists in keeping parts stable during maintenance.

What is the specific purpose of needle nose Vise-Grips?

Needle nose Vise-Grips are designed for reaching into tight spaces where standard pliers cannot fit. They are well-suited for grasping small items, bending wire, or holding objects in precise positions, particularly in electrical and electronics work.

What are the steps to properly unlock Vise-Grips?

To unlock Vise-Grips, one must locate the release lever near the handle of the pliers. Then, they should squeeze the handles slightly to reduce tension and press the release lever inward, which will allow the jaws to open.

In what applications are locking pliers most effectively used?

Locking pliers like Vise-Grips are most effective when a strong and steady grip is needed on an object without continuous pressure from the user’s hand. They serve well for tasks such as holding metal pieces during welding or providing a temporary handle on a broken tool.

Can you explain the different types of Vise-Grips available?

Vise-Grips come in various styles, including curved-jaw, straight-jaw, and needle-nose configurations. Curved-jaw pliers are optimal for gripping round objects, while straight-jaw versions work best on flat surfaces. Specialty Vise-Grips also exist for tasks like wire stripping or sheet metal work.

What is the correct way to use a Vise-Grip wire stripping tool?

A Vise-Grip wire stripping tool should be adjusted to match the gauge of the wire being stripped. Once the wire is placed between the stripping jaws, the tool can be locked and then pulled gently to remove the insulation, leaving the wire intact.