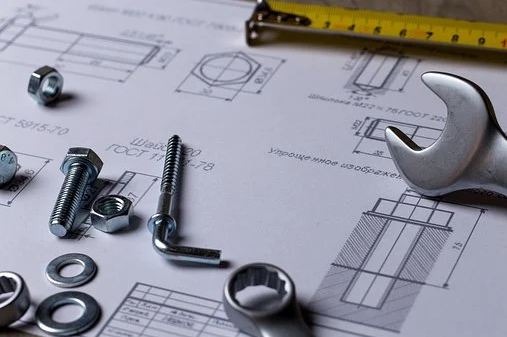

Nuts are small metal hardware that is threaded internally to hold on to bolts and screws. They are used to connect two applications and act as mating bolts.

Washers are slid onto the fasteners to promote security and absorb the vibrations off. They equally distribute the weight all over the surface, spacing and carrying a heavy load. They are a game-changer being thin pieces of metal.

Types of Nuts

Nuts come in a variety of shapes and sizes, which are all described below.

1. Acorn Nut

Acorn nut or crown nut gets its name from its shape like a dry nut named acorn also. It is a dome-shaped nut that covers the threads of the screw. That is why it also has the name-blind nut. It is a knot that has a dome top to cover the drift. It is to block contact with the external thread to protect it or other things it would scratch. In addition, it gives a more finished appearance. These screws exist made of brass steel, stainless steel, low carbon content, or nylon. It can also be chrome plated. If the acorn nuts are high in standard, they will have a wider knot and protect extra long studs. Self-locking acorn nuts deform threads in the hex area to generate a tight friction fit, which keeps the nut from shaking loose.

2. Wing Nut

Having two wings on each side of the nut also gains itself the name butterfly nut. This nut can be loosened and tightened very easily by hand. It is bulky compared to other nuts, so it can get fastened by simply twisting them in. To make them loose, twist them out, no need for tools. It is also named a thumb nut because you can function it by putting pressure on your thumb.

A wingnut is not the safest nut because of how easy it is to loosen it. Nut washers may get used to secure wingnuts. Wingnuts get used to joining objects together. It gets used in places that require frequent change of the nut. So, it is for a temporary hold.

3. Flange Nut

Flange nut gets its name by having a flat brim or a flange on one side of the nut. This collar ensures more strength in fastening and protection. The flange equally distributes the pressure and energy of the nut. Underneath the brim, the nut has seen jagged edges face the opposite way from the rotation that will loosen up the nut. These sharp edges cause scratches on the surface. These nuts get used by the automobile and electronics industry. Not all flange nuts come with a serrated edge, it also has a plain surface. Flange nuts with a plan surface get used for connecting metal and wood.

4. Well Nut

Well nuts, also called raw nuts, consist of a hole shaped like a well on one side and a flange on the other side. Flange secures the bolt or the screw from slipping while being drilled in. The hole is all the way threaded to the surface for smooth fastening. Well, nuts get used to fill up punctures or attach pieces of hardware. To install a good nut, insert the nut into a hole or drill a hole into an exterior. Slip a washer into the screw for security. And ground it into the well of the nut.

5. T-Nut

T-nut has an elongated body and has a flange at one side. The long side of the nut has a hole in it. Its flange is shuriken-shaped. It has grippers poking underneath from every four points. T-nut is used to attach big pieces of material due to having a stronghold. It mostly gets used in woodwork. Install the T-nut in a drilled hole. Insert a screw or bolt along with the washer into the threaded hole of the nut. When you tighten the screw, the flange poking points will dig deeper into the material, promoting a good grip.

6. Square Nuts

A square nut is a small four-sided nut that may be used as a hidden nut. It can easily be hidden inside the material, while fastening is possible due to its small size. Square-shaped nuts get mostly paired with square-shaped screws. Square-shaped nuts are one of the first nuts invented. They get used to complicated construction because of how strong they are. They are impossible to rotate with your hands or even a general wrench. It is easy to install with the use of a proper tool. Its four edges may result in scratches. But, the use of washers will protect your surface from getting damaged.

7. Insert Nuts

Insert nuts are threaded both internally and externally. There and two types of insert nuts:

- Hammer-in

- Screw-in

The hammer-in gets hammered in the hole, and the screwed-in gets screwed with the help of a screwdriver. Insert nuts are threaded externally to have a solid grip on the drilled hole, making it impossible to take them out. These nuts get screwed in the drilled hole then a fastener is twisted into the internal part of the nut. For specific or highly specialized applications, these nuts may require custom machined parts to ensure optimal fit and functionality. These nuts get used where a stronghold is required.

Types of Washers

1. Flat Washer

A flat washer is the most basic type of washer. Flat washers get used to cover holes and uneven surfaces. There are different types of washers with a variety of thicknesses and shapes. If you are looking to create spaces between materials or appliances, look for a flat washer with a bigger diameter. They are perfect for soft surfaces and, because of the even flat surface, it distributes the pressure equally.

2. Belleville Washer

Belleville washer by Julien Belleville has been around for a century. It is also called a cone, disk, or canonical washer. They have a shape like an upside-down cup with its upper part pulled higher than the lower portion. They are spring washers, great for bearing heavy loads. When a heavy load gets put on this washer, it compresses. When the weight gets lifted, the washer springs back out to its regular shape. Belleville washer does not come out while going through vibration. Unlike the other washers, its cone shape bounces back, and trembles stay out.

3. Wave Washer

Wave washers are one of the most effective washers. It has a repeated wave pattern all around the washer. They are made for absorbing vibrations equally and for spacing. It is effective on heavy loads. It equally distributed the weight around the washer and surface.

4. Tooth Washer

The tooth lock washer has teeth poking from the washer. Tooth washers get used to provide extra grip on the structure. There are two types of tooth washers, internal and external tool washers. The tooth washer has internal teeth.

Each of them has a different purpose. The inner teeth have a stronghold on the bolt, securing it from getting lost. The external tooth lock washer has the teeth outwards. When the bolt or screw is getting fastened, the teeth get tightened to the surface. The teeth dig into the surface and make it impossible to twist it out with ease.

5. Split Washer

A split washer is a ring that is cleaved from one side. Split washers get gilded on the fasteners by opening the cut area a bit. These washers get used to creating friction and tension. They prevent the screws from loosening or slipping away.

There is a theory that the split washers are not effective. But in actuality, they do. But only where there is little to no pressure. If a heavy load gets added on them, they get flat. They are used to keep the bolts or screws in place and act as a spring for them.

6. Tab Washer

If you are looking to secure applications that will be getting used in crippling heat and heavy load requiring high torque, a tab washer is for you. Tab washer is a thin circular washer with a tooth poking out. It prevents the bolt or screws from rotating and keeps them secure. After tightening, the tooth of the tab washer is bent to secure it and prevent it from turning. The bent tooth digs into the material and provides extra protection.

This washer cannot get used again because of the curved tooth after fastening. It gets used at the corner and edges.

Bottom Line

Nuts and washers are frequently required. Having their knowledge appears to be a given nowadays. The article ensures that you have all of the information you need.

You may now utilize both of these fasteners and hardware!