A nail is a type of fastener used in construction and carpentry. It is a slender metal shaft with a sharp, pointy tip on one end, and a flattened head on the other. The pointed end is called point, the flattened end is called head, while the shaft is referred to as shank. A nail is usually pounded into position by striking a hammer directly on the head. It is also likely to bend or break when not appropriately driven.

Nails have been used in different kinds of construction for at least 3,000 years. They are commonly used to fasten one or more objects with each other. You can use them to hold pieces of wood, plastic, masonry, drywall, and even concrete. They are helpful in places where a screw is not needed.

There are several different types of nails, each with its own function and purpose. They are made in a variety of lengths and diameters. A nail must have adequate shank length and sufficient strength to properly fasten different materials. It is the friction that holds these narrow pins in place. That’s why some designs may include roughened, grooved, or twisted shanks that strengthen the grip. With all of this mind, let’s explore the different types of nails to understand their uses better.

Types of Nails

Following are the most popular types of nails that you’ll find in the aisle of any hardware store.

1. Common Nails

Common nails are ordinary all-purpose nails widely used in construction and woodworking projects. They have a round head that is visible on the surface. They have a heavy shank that makes them sturdy and reliable. Their strength makes them a good choice for projects where function is more important than aesthetics. Common nails are often used for joining timber and other materials.

2. Finishing Nails

Finishing nails are similar to common nails; the only difference is that these have much smaller heads that sit in line with the wood surface to provide a neater finish. The smaller heads also indicate that the wood is less likely to break.

To entirely hide the head, you can use a nail to recess it. Because of this, they are often used in furniture and decorative or exposed wood. You can also use brass finishing nails to add a decorative touch.

3. Box Nails

Box Nails look a lot like common nails, but they have a thinner shank. This makes them less sturdy and more suitable for building boxes. With a thinner shank, these nails are less likely to split thin pieces of wood. They are a great choice for light construction work because of their slim design. Box nails are often galvanized to prevent corrosion.

4. Roofing Nails

Roofing nails have a large head and are most commonly used for roofing purposes, such as nailing shingles, attaching asphalts, and other tasks. The large head holds the thin material in place and prevents it from breaking loose. Roofing nails are also usually galvanized to avoid rusting.

5. Masonry Nails

If you want to drive nails into a rock hard surface, like brick or concrete, masonry bricks are what you need. Masonry nails are available in various styles, the most common being rectangular sections with fluted shafts. They are made this way to prevent breaking or bending as you drive them into hard surfaces. These nails are more rigid and thicker with small heads, usually made of hardened zinc, which is more robust. You can use these to join wood with stone or brick.

6. Drywall Nails

Drywall nails have a ringed or barbed shank for improved gripping strength. The barbed shank also allows them to operate easily beneath the surface of the wallboard for a concealment while reducing tearing of drywall paper. These nails are specially used for hanging drywall. You can also use them on gypsum boards.

7. Double-Headed Nails

Double-headed or duplex nails have two heads on one shank. One of these secures the nail against the work, while the other allows easy removal. They are driven in until they reach the first head, whereas the top head stays above the surface, making removal simple.

These nails are commonly used to bind scaffoldings and other temporary structures in place.

8. Casing Nails

A casing nail has a tapered head that can be placed flush or below the wood surface. These nails appear a lot like finishing nails, but are a bit big and thick. They have a better holding power hence are more suited for projects that require a little extra holding power. You can use these while attaching moldings such as window and door casing.

9. Annular Nails

Annular or ring-shank nails feature rings along the shank that provide better grip and added resistance when used in wood. These nails separate the wood fibers, which then lock back into the rings, preventing removal. They are usually made using carbon steel without any protective coating, so can rust in moist conditions. This type of nails is useful for drywall or deck board applications, thanks to their pullout-resistant feature.

10. Cap Nails

Cap nails have a spiral shank and a plastic cap just below the nail head. The shank holds the fastener in place, while the cap secures wrap, felt, or foam insulation and prevents tearing. Its polyethylene construction also prevents leaks. They are useful for attaching roofing felt, house wrap, tar paper, and insulation foam board.

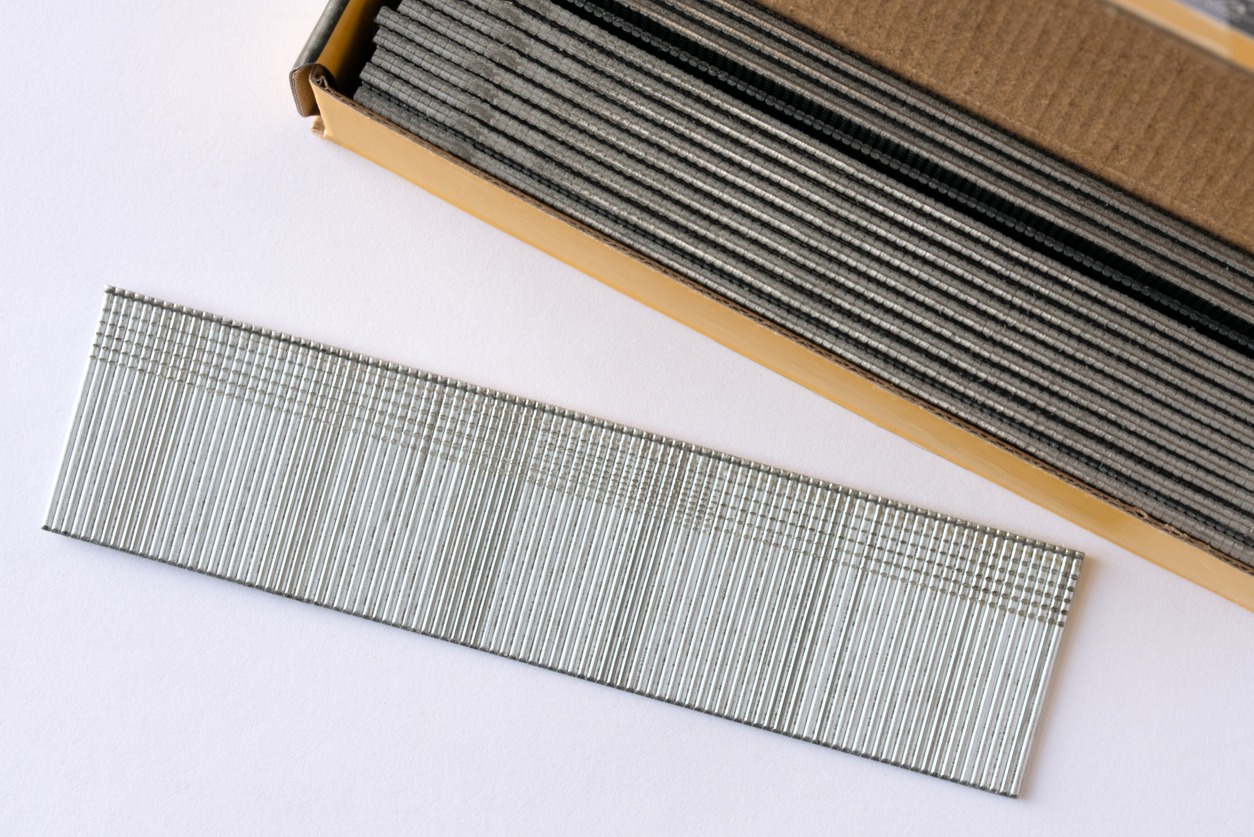

11. Brad Nails

While casing nails are bigger than finishing nails, Brad nails feature a smaller size. These nails are more delicate than regular nails and have a smaller head. They are usually no more than one inch in length. The small size and diameter makes them easy to conceal in wood trim or paneling. They are useful for performing basic cabinet work, making frames, and attaching plywood paneling.

12. Carpet Nails

Carpet nails have a flat top, a shaft, and a pointed end. The small and sharp nails are used for affixing carpets to the floor. When you put and secure it in place, it usually stays into and around the carpet’s edges.

13. Upholstery Nails

Upholstery nails look a lot like thumb tacks. They are designed with a wide head and a narrow pointy shank. These nails serve a dual purpose: holding the material in place and adding decorative accents. Upholstery nails are usually bright and very shiny. Since they are targeted for indoor use, these nails are not rust-resistant. You have to rub them with a soft cloth to keep them shiny.

14. Staple Nails

Just as a stapler pin fastens together pieces of paper, a staple nail is used for fastening various materials together. These nails are driven in using a nail gun or hammer. Where smaller pins are used to keep papers together, a staple nail or fastener is useful in roofing, masonry, corrugated boxes, and other heavy-duty applications.

15. Spiral Flooring Nails

Spiral flooring nails have a spiraled shaft and were traditionally used for subfloor nailing. Nail guns and specially made nails have mostly replaced these nails in today’s construction work.

Conclusion

Nails have always been a crucial part of construction and woodworking projects. They fasten different materials together and keep them securely in place. Realizing their importance, tool manufacturers have come up with numerous types of nails, each designed to serve particular purposes. Above we have listed some of the popular ones. Knowing about the different types is important because it will help you figure out the right nails for your needs.