The golf ball is an integral part of the game of golf. Truth to be told, the gameplay revolves around it. From employing the proper posture, getting the correct grip, applying the right swinging technique, angling in the right direction, and accounting for speed, distance, and rotations, all those boil down to the ultimate goal of getting the ball into the hole for a score. As such, it’s no surprise that it went through various transformations across many centuries to get to its current form today. In this article, discover the evolution and history behind the golf ball.

Wooden Golf Balls

Based on popular accounts, it is believed that golf’s earliest games were played in the eastern region of Scotland in the 14th century, and the first clubs and balls were made of hardwoods such as box and beech trees. However, some say that these wooden balls weren’t actually used in golf games in Scotland, but rather in other stick and ball games similar to it.

The wooden balls were pretty smooth, which means they do not possess decent handling properties. While they were durable, they could only travel up to 75 meters. As such, the likelihood of them being utilized by link golfers in Scotland is pretty low. Thus, the usage of wooden balls remains an assumption, and debates continue to circle whether golfers actually used it.

Hairy Golf Balls

From 1486 to 1618, Scotland imported a small, hand-sewn leather golf ball stuffed with cow’s hair or straw from the Netherlands. By 1554, Scotland also started producing their own hairy golf ball. It was utilized up until the early 18th century due to its affordability, despite having a new and famous type of ball being introduced in 1618. However, the introduction of the other ball relegated the hairy ball to its status as the common ball.

Featherie Golf Balls

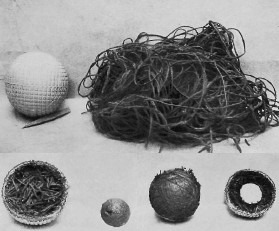

In 1618, the “Featherie,” the most famous of all golf balls, was developed and introduced. It pretty much resembles the hairy golf ball, which used a leather-stitched round pouch. The difference was it made use of chicken and goose feathers as its filling, producing a harder ball. Thus, allowing it to fly greater distances.

To produce the featherie, feathers are boiled and softened before being stuffed into an also wet leather pouch. As the ball dries, the former expands while the latter shrinks, giving the ball’s preferred hardness. Afterward, it will be painted, usually in white, and be added with the ball marks. Creating a featherie became a tiresome and time-consuming process, leaving ball makers to produce only a few balls each day. As such, the featherie became pretty expensive, amounting to 2-5 shillings, equivalent to 10 to 20 dollars in present rates.

Aside from being costly, the featherie also had some disadvantages. First, they were very difficult to shape perfectly round, affecting the trajectory and leaving balls flying erratically upon contact. Second, they were prone to splitting up, either after being hit by the club or smashing on the hard ground. Lastly, featherie balls must never get wet as it will cause stitches to decay, behave differently, and lose their distance.

Though there were many drawbacks, the featherie was still a massive improvement compared to the wooden and hairy balls and was still embraced as the standard golf ball until the 19th century.

Guttie or Gutta Percha Balls

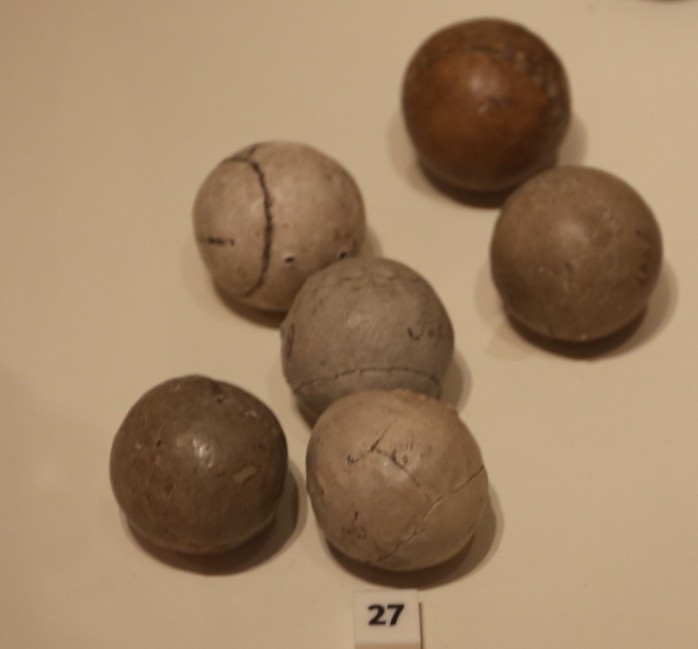

In 1848, Dr. Robert Adams Paterson created the first molded golf ball called the Guttie or Gutta Percha balls. It was made from dried sap of different Malaysian Sapodilla trees. The sap possessed a rubber-like feel, which could be softened through heating, shaped round while it’s hot. Thus, producing the spherical ball after it hardens.

The guttie was a solution to the many downfalls of the featherie. First, these balls boast mass-manufacturability, making them very inexpensive. Second, they are easy to reform if in case they get damaged or out-of-shape, compared to the featherie who used to split open. Third, the guttie had more aerodynamic properties. It was even accidentally discovered that the marks left on the ball made it even more aerodynamic. Thus, makers started to veer away from smooth guttie and intentionally incorporated indentations using chisels, hammers, or knives to give the guttie even more consistent ball flight. Soon, different patterns were used. One of the most popular was the “bramble,” named in resemblance to the fruit, which had protruding nubs instead of indentations.

Rubber Core Golf Balls

Another innovation in the golf ball happened in 1898 after Coburn Haskell. While waiting for Bertram Work for a golf outing, Haskel wounded a rubber thread into a ball and discovered that it had lots of bounce. Work suggested developing the ball but sporting a covering, resulting in the rubber-core Haskell golf balls. The ball was initially made with a solid round or liquid-filled core, which was then wounded with a rubber thread and skinned with sap from the Balata tree. As thread-winding machines were soon discovered, the Haskell became massively procured, putting the Guttie into oblivion.

The Haskell ball initially had the same bramble patterns, but the dimpling pattern was applied in 1905, which decreased drag, but maximized the lift. The ball had improved flight pattern and controllability, giving birth to the golf ball look we’ve been attuned to.

More innovations were made, with the Haskell being the standard of the modern golf ball design. In the 1960s, Surlyn, a new synthetic resin, along with new urethane blends, replaced the Balata sap and provided better durability to the golf ball. Layering techniques were also employed in the subsequent decades to help with different aspects of the golf game, resulting in one-piece, two-piece, three-piece, or four-piece golf balls. With the continuous advancement of technology and with golfers’ endless desire for improved gameplay, there are undoubtedly more developments to come for the golf ball.