We currently live in a golden age of 3D printing as you don’t have to be an engineer or a scientist to make your own 3D model. For home users, 3D printers make sense when you have to print customized objects that you cannot find anywhere else. Users can get started in 15 minutes and all they need to be careful about is safety and ventilation. Failures are now a learning experience and not costly mistakes because most 3D printers have advanced safety features built into them.

Buying a 3D printer can be a daunting task, especially for people new to the technology. This guide aims to make it easier for beginners to make the buying decision and covers the basics to equip them with the essential knowledge.

What Is A 3D Printer?

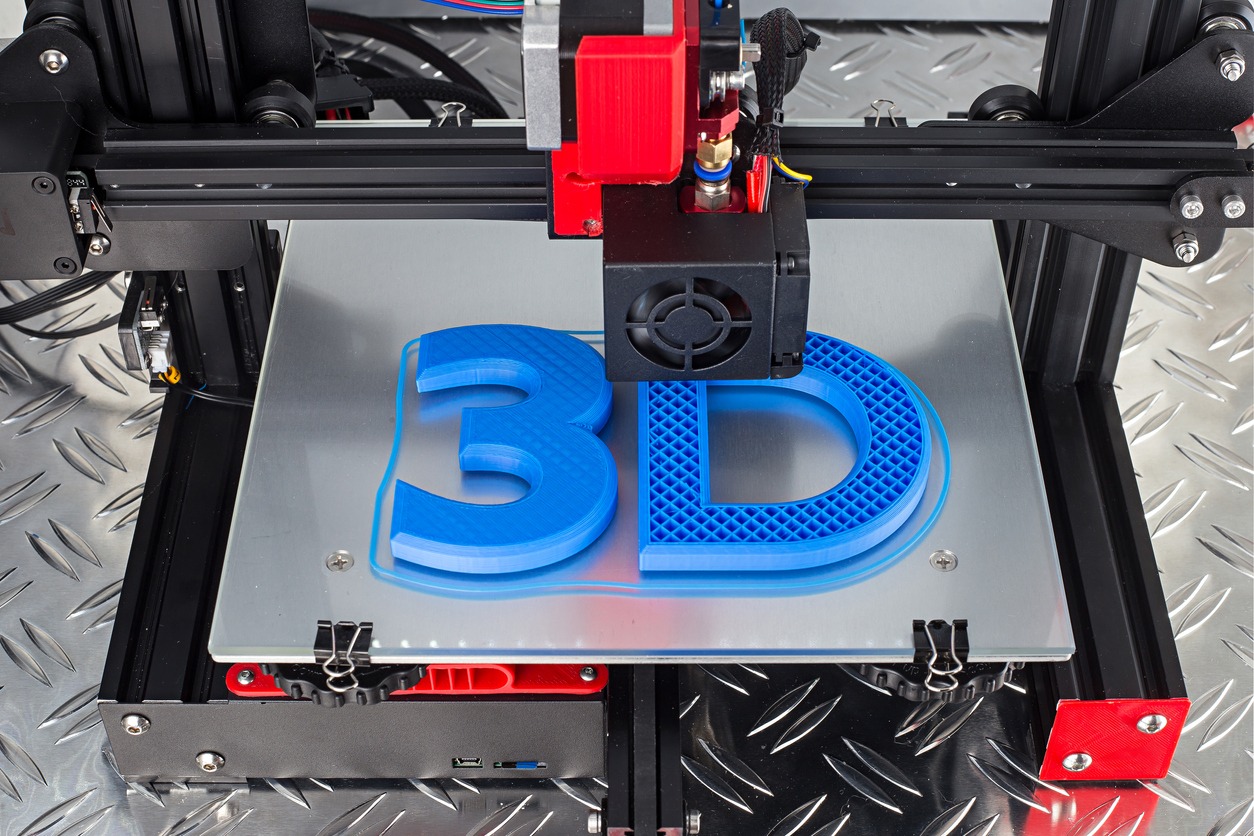

A 3D printer is a special kind of printer that can make 3D models, prototypes, and other components by using an additive manufacturing process. This means it builds the object layer by layer, using a computer-aided design or software-generated 3D design. With a 3D printer, you can create a physical version of a prototype or design directly from a digital file.

How Does A 3D Printer Work?

3D-printers work by taking a digital design and slicing it into thousands of thin layers. Then, the printer builds the object one layer at a time using different materials that are extruded and stuck together. This layer-by-layer process allows for the creation of intricate designs with fine details. You could even print something as complex as a whole bike, with all its parts already assembled. It’s amazing how far this technology has come and the possibilities are endless.

Types Of 3D Printers

The use of 3D printing is rapidly gaining popularity across various industries, including manufacturing. With a whole range of 3D printers available, we have a lot of different options to choose from with the following 3D printing methods/3D printers being the most common:

Stereolithography (SLA)

SLA is the world’s first 3D printing method invented in 1986 by the founder of 3D Systems, Chuck Hull. SLA Printers use the Polymerization technique to create objects from a photopolymer resin cured by a light source. The process involves using galvanometers and a laser beam to cure the resin layer by layer, and a recoater blade to spread each layer evenly.

Specific Laser Sintering (SLS)

SLS is a 3D printer that creates strong plastic parts with living hinges and snap-fits for functional testing. It uses material such as nylon or metal, layer by layer, creating a solid object.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), is a 3D printing technology that uses a material extrusion process to produce physical models layer-by-layer. FDM is commonly used for electrical housings, structure and fit testing, jigs and fixtures, and investment casting patterns. FDM also offers a good surface finish and full-color capabilities, with a variety of materials available for use.

Digital Light Process (DLP)

DLP 3D printers are known to have faster print times compared to SLA 3D printers. This is because DLP printers expose entire layers simultaneously, while SLA printers trace each layer using a laser. These two technologies are typically used to produce polymer models for applications such as injection molding, jewelry, dental appliances, and hearing aids.

Multi Jet Fusion (MJF)

Multi Jet Fusion (MJF) is a 3D printer that uses an inkjet cluster to melt nylon powder and create objects with a smooth finish and strong mechanical properties. It’s faster than some other 3D printing methods and can even make things in multiple colors or with different materials. During printing, a special material helps support the object being printed.

Types Of Material Used in 3D Printing

Acrylonitrile Butadiene Styrene (ABS)

- Suitable for kitchen appliances, musical instruments, toys, and more

- Used to create Lego bricks

- Durable and heat-resistant

Polyvinyl Alcohol (PVA)

- Used to create support structures during the 3D printing process

- Found in paper adhesive, hygiene products, and fishing bait containers that dissolve under water

- Water-soluble plastic

Polylactic Acid (PLA)

- Environmentally friendly and biodegradable

- Can be used in surgical implants, food packaging, disposable garments, and more

- Available in a range of colors

Before selecting a material, it’s important to check your printer’s filament diameter. Most printers only accept one size, either 1.75mm or 3mm, so it’s essential to check before buying. With these materials readily available online, it’s easy to experiment with different options and create exciting new 3D printed objects.

Key Specifications

It is crucial to pay attention to important specifications when buying a 3D printer. The most important specifications to consider are listed below, and play a crucial role in determining the suitability of a printer for your needs:

Resolution

When selecting a 3D printer, it is important to consider its resolution. Resolution in 3D printing refers to the smallest possible movement that the nozzle can make while depositing material to build objects. The level of resolution impacts the level of detail in the final printed objects. Some 3D printers can make more precise movements than others, enabling higher resolution and more detailed prints.

The ability to make smaller movements allows for more material deposits, resulting in finer details in the final object. Therefore, selecting a 3D printer with a higher resolution is essential for those who require more detailed and intricate 3D prints, but a higher resolution also comes at a premium.

Speed

The rate at which the 3D printer extrusion system moves while depositing filament to build objects is known as print speed. This speed is usually measured in millimeters per second (mm/s). For Fused Filament Fabrication (FFF) 3D printers, the print speed range typically falls between 40 mm/s and 150 mm/s. This speed specification is an essential consideration when selecting a 3D printer since it affects the efficiency and effectiveness of the printing process. The extrusion system’s movement speed determines how fast the filament is deposited to form the final object during the 3D printing process.

Print capacity

To print an object, the size of the print bed where it is built determines the print capacity of a 3D printer. Since print beds come in different sizes for every printer, it’s vital to check the bed size before buying a 3D printer.

Obtaining 3D Models

To obtain a 3D model for 3D printing, you can either create it yourself using 3D modeling software or download pre-made models from online sources. Creating a model from scratch can be challenging, requiring time and expertise. Online sources offer a variety of models created by enthusiasts, which can be downloaded for free or purchased for a small to moderate fee. However, ensure the model is compatible with your printer’s specifications.

STL files

STL files are used in 3D printing and contain all the necessary information to create a 3D model. The file is composed of coordinates for each triangle that makes up the model’s surface. 3D printers use this data to build the object layer by layer, following the instructions in the STL file. These files are essential for creating precise and high-quality 3D prints and are widely used in various industries.

Preassembled vs Kits

When purchasing a 3D printer, you have the option of choosing between a fully assembled device or a kit. While a kit may be less expensive, it requires assembly which can be challenging for a beginner. However, assembling the printer can provide a better understanding of its parts. On the other hand, a fully assembled printer is ready to use right out of the box and eliminates the need for assembly. This option may be preferable for beginners who want to avoid the complexities of assembly. Although it may cost more, it provides a hassle-free printing experience.

Things to Consider When Buying a 3D Printer

Know Your Requirements

To ensure you get the right 3D printer, it’s essential to understand your needs first. Consider the size and complexity of the objects you want to print, as well as future projects you may have in mind. Also, remember that you don’t necessarily have to own a 3D printer to create 3D models as there are online services available that allow you to print a 3D model for a fee.

Budget

The cost of a printer depends on a few factors, mainly the printing method and the printer size. Industrial methods, especially those involving metal, are more expensive. 3D printers are available in different shapes, price points, and sizes ranging from compact $200 3D printers to massive printers for large projects.

Avoid Impulsive Behavior

It can be easy to get caught up in the excitement and make an impulsive purchase, but you don’t want to end up with a pricey piece of equipment that just collects dust. Take the time to consider which printing method is best for you and your budget. If you’re looking for a more affordable option, there are smaller desktop 3D printers that use FDM or SLA printing methods for around $200. Or, if you’re up for a challenge, you can save even more money by purchasing a DIY kit and assembling the printer yourself. Just remember that it might take some time and effort to put it together. By taking the cost and your needs into account, you can make an informed decision and invest wisely in a 3D printer.

Space requirement

When you’re setting up a 3D printer, keep in mind the space requirements for the device. The size of the printer, along with the tools and materials, will determine how much space you’ll need. You’ll also need a stable surface that minimizes noise during operation. For most 3D printers, a minimum of four square feet on a sturdy table or shelf should be enough. Don’t forget to pick a good location for your printer, too. Avoid high humidity or temperature fluctuations that can hurt print quality. By giving your 3D printer enough room and a stable spot, you can ensure efficient printing.

Safety

Be mindful of safety when using 3D printers. Due to the heat involved, it’s important to handle the printer and materials carefully to avoid burns. Also, the printing process can release fumes, particularly when using ABS plastics, so adequate ventilation is necessary. Ensure that any 3D printed household items are food safe and consider that FDM-printed objects may harbor bacteria due to their porous surfaces. Coating the object can help, but it’s best to limit their use in the kitchen.

Best 3D Printer Brands

Crealty

There are many popular brands in the 3D printing space originating from China. When it comes to bang for the buck, Creality is a popular brand, particularly with their Ender 3 series, which offers affordable and user-friendly models. With their reputation for success and focus on innovation, it’s no surprise that Creality is a favorite among 3D printing enthusiasts.

Prusa Research

The company makes open-source 3D printers, which are known for their reliability and high quality.

Ultimaker

The Dutch company makes high-end printers targeted at professionals and businesses and are used for small-batch manufacturing and prototyping.

MakerBot

The USA-based company offers both SLA and FFA 3D printers with models ranging from entry-level to professional models.

Elegoo Mars

The company produces an affordable range of SLA 3D printers and is a great option for beginners and budding enthusiasts.

Conclusion

There are various varieties of 3D printers with each having its own advantages and disadvantages. 3D printers have become more affordable and functional than they were just a decade ago. The printer needs to be programmed to leave gaps in the right places so that all the components can be integrated into a single object without the need for additional tools. It’s crucial to avoid making impulsive purchases, study customer reviews of leading companies, and contrast them before choosing the product that best suits your needs.