Fasteners are used to create a temporary connection between two things and join them together. In other words, you can remove it, and the different pieces should fall apart without any damage. A welded joint, for example, wouldn’t be joined in the same sense as it would be with nuts. The only exception to this rule are rivets that are classified as fasteners yet form permanent joints.

A nut is another popular fastener with a threaded hole; it secures numerous things together and tightens them. Nuts are typically used with bolts that hold the nut in place as it is being tightened. The pair of nuts and bolts are secured by friction between their threads, minor stretching of the bolt, and compression of the pieces, which hold them together tightly.

When it comes to applications, lock washers, jam nuts, specialized adhesive thread-locking fluid (such as Loctite) can be used along with safety pins or lock wires when used with castellated and nyloc nuts. Aside from that, slightly oval-shaped threads can also be used when vibration or rotation is a cause for the nut to loosen up and fall apart.

Choosing the right type of nuts for your DIY job is very important, as it can save you from running into problems later on when working on a project. However, if you are having a hard time finding the right kind of nut, let’s discuss all the things you need to consider to get suitable nuts for the job.

Things to Consider Upon Choosing the Right Kind of Nuts

1. Checking How They’re Applied

Before you start looking for a suitable nut fastener, you need to understand its usage first. Different fasteners have different uses; if you’re wondering about the exact application and the kind of nuts you need, you have to figure out how they are applied and used to have an idea of what they can do.

2. Grading of Nuts

Another best thing you can do is get familiar with the standards that always govern fasteners and their grades. ASTM A307, for example, states that a good nut should have about 60ksi of tensile strength to be considered a high-quality nut for general use.

3. Choosing the Right Supplier

Knowing how to use the nut fastener can be beneficial for you when you check with a supplier. It includes various processes and elements to consider, and having the right vendor is an essential part of it.

If you are purchasing a fastener for the first time, search for a supplier with a good rating, someone with knowledge and expertise to help you. Having a reliable supplier is critical when selecting any fastener. Unfortunately, many vendors sell fake products that can easily deceive you if you’re not an expert.

4. Types of Nuts

When choosing the right nut, you have to consider the type of nut you’re looking for, depending on the nature of the work. Nuts are available in various materials, sizes, groove types, and shapes. And with so many options, the nut selection is restricted to its matching bolt selection. The threads and the size of the bolts should match the thread and size of the nuts.

Here are some nuts that you can check out:

5. Wingnut

A wingnut, also known as a butterfly nut, consists of two large metal wings on each side so one can easily tighten and loosen it by using your hands. These nuts are meant to be released and tightened with your fingers in low-torque applications that need rapid or regular adjustment or disassembly.

6. Coupling Nut

These coupling nuts are also known as extension nuts. These nuts connect two thread rods or pipes, particularly threaded rods or pipes of different diameters. Coupling nuts are commonly used to tighten rod assemblies or to push a finish rod assembly outward. They are usually built in a hex form for wrench grip.

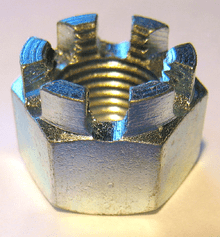

7. Castle or Castellated Nuts

Castellated nuts are those that have a turret-like appearance. When you fasten the turret-like structure, it leaves a gap that aligns with the bolt. The snug fit keeps the bolt firmly in its place. So you don’t have to worry about the bolts loosening all the time.

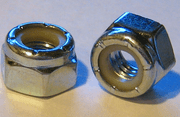

8. Locknuts

Nuts are used to secure bolts in place, while locknuts are used to hold nuts in place. These nuts offer a more accessible and cost-effective solution for protecting against the loosening caused by vibrations. They’re also known as nylon lock nuts or nyloc nuts.

9. Slotted Nuts

These nuts are used mainly as safety nuts; they are slotted to accept a cotter pin or wire that goes through a drilled hole in the bolt and secures it. These nuts, usually used as safety nuts, are slotted to accept a cotter pin or wire that goes through a drilled hole in the bolt and secures it.

10. Flange Nuts

A flange nut has a larger flange on one end that works as an integrated washer. This washer distributes the nut’s pressure over the secured item, limiting the possibility of harming the part and making it less prone to loosening due to an uneven, fastened surface.

11. Square Nuts

These are four-sided nuts often used as blind nuts in furniture. They are also used in rail channels to prevent rail twisting when pressure is applied. They are also an excellent basis for concealed fasteners in the metal channels.

12. Hex Nuts

These nuts are the most commonly used ones, and you can find them on anchors, bolts, screws, studs, threaded rods, and any other fastener having machine screw threads. Hex is an abbreviation of hexagon, meaning something with six sides, and since they also have six sides, they’re called hex nuts.

1. Types of Materials Used in the Nuts

Many materials provide different features depending on your fastening requirements. The nuts used in cold or acidic conditions cannot be the same as those in the boilers.

Here are some materials that you should look for when choosing a nut:

Carbon Steel

Carbon steel offers a higher range of durability; therefore, it’s no surprise that it’s the most common material used in nuts. They have a wide variety of tensile strengths; you can use low carbon steel similar to ASTM 307 Grade B for large hex nuts. The treatment can enhance the nut’s strength, allowing it to withstand extra force. In addition, it enables them to work with valves, high pressure, and flanging.

Steel Alloys

These are made from steel alloys since alloys improve steel strength. They have a lot of power, but they’re fragile. If this is your preferred steel, then proceed with caution. A reaction with hydrogen can cause brittleness. To combat this, you can use zinc-coated steel bolts.

Choosing the Right Nuts – Knowing What to Look For

Choosing the right kind of nuts might seem very simple, but there’s more to it than simply buying them. Before buying them, you must consider various things. The durability, the material, and cost are also important things to consider when choosing nut fasteners. After considering the factors mentioned above, you would have an idea of the different kinds of nuts and be able to get the best type that you require.