The hobby of model making is a creative and rewarding activity in which one creates miniature replicas of a variety of different things, including scenes, vehicles, and objects. Intricate models are constructed by enthusiasts employing a wide range of materials, including plastic, wood, metal, and resin, in conjunction with specialized construction tools. This is a broad hobby that encompasses a variety of subfields, such as scale models, dioramas, miniature figures, and architectural models. Model making is a pastime that requires patience, precision, and attention to detail; as a result, it can be considered both educational and therapeutic. Model building is a hobby that is enjoyed by many people and is one that provides them with a sense of fulfillment and engagement because so many enthusiasts join communities and take part in exhibitions to share their work and learn from others.

Both 3D printing and robotics have brought about a sea change in the model-making industry. These technologies provide highly detailed and functional models with an array of cutting-edge tools and methods for their creation. Printing in three dimensions (also known as 3D printing) enables the fabrication of intricate parts with speed and precision, and robotics enables automation and movement in models. They have worked together to broaden the scope of what is possible when it comes to the construction of scale models, turning the activity into a dynamic and cutting-edge hobby.

In the world of model making, the combination of 3D printing and robotics has ushered in a revolution in terms of the level of precision and customization that is possible. This game-changing combination gives hobbyists the ability to create models with unrivaled accuracy and customize them to meet their specific tastes and requirements, thereby opening up exciting new horizons in the world of miniature craftsmanship.

What is 3D Printing?

The creation of three-dimensional objects from digital design files is the process that is referred to as 3D printing, which is also known as additive manufacturing. It entails building an object one layer at a time and adding material in stages until the end product is finished. The following is a concise explanation of how the 3D printing process works:

1. Digital Design

The first step in the process involves developing a computer-aided design (CAD) model of the object in question using a 3D modeling program. This digital model will serve as the blueprint for the actual thing that will be created.

2. Slicing

After that, the digital 3D model is sliced into thin horizontal layers by using software designed specifically for this purpose. This piece of software will produce a set of instructions known as G-code that will direct the 3D printer as to how to construct each successive layer.

3. Printing

The G-code instructions are followed by the 3D printer as it begins the process of layer-by-layer construction of the object. Depending on the configuration, it deposits material, which may be composed of plastic, resin, metal, or a variety of other substances.

4. Layer Bonding

Depending on the particular 3D printing technology that is being utilized, each layer of material is either cured or fused before the next layer is added. The melting of plastic filament, the curing of liquid resin with ultraviolet light, and the sintering of metal powder with lasers are all common methods.

5. Building Up

This process of building an object layer by layer is repeated by the 3D printer until the final product is complete. It could take a few hours or even a few days, depending on how complicated the object is and how big it is.

6. Post-Processing

To attain the desired level of finish and functionality in certain objects, additional post-printing processing steps, such as cleaning, sanding, painting, or assembly, may be necessary after the printing process has been completed.

The use of 3D printing has expanded into many different fields, including the aerospace industry, the automotive industry, healthcare, architecture, the fashion industry, and of course, hobbies such as model making. It provides benefits such as rapid prototyping, the ability to customize products, a reduction in the amount of material waste, and the ability to create complex geometries, all of which would be difficult or impossible to accomplish using traditional manufacturing methods.

What is Robotics?

Robotics is a multidisciplinary field that encompasses the design, construction, programming, and operation of machines or robots to carry out tasks in a fully or partially autonomous manner. These robots may take the form of either physical machines or software agents, or they may combine the two. The creation of machines that can perceive their surroundings, perform information processing, and interact with the real world is the goal of robotics, which draws from a variety of subfields within engineering, computer science, and other academic disciplines. The following is a list of important aspects of robotics:

1. Hardware

The field of robotics requires the development of physical robot hardware, which can range from uncomplicated, single-function machines to highly complex, multifunctional robots that contain a variety of sensors, actuators, and mechanical components.

2. Sensors

Robots can gain a perception of their surroundings thanks to the various sensors (such as cameras, infrared sensors, LiDAR, and touch sensors) that they are outfitted with. Robots can use the data provided by these sensors to make decisions about their environments and navigate through them.

3. Actuators

Robots are only able to interact with their surroundings through the use of a component called an actuator. Actuators can take many forms, but the most common ones are motors, wheels, arms, and grippers. Actuators give robots the ability to move and manipulate objects.

4. Control Systems

The field of robotics entails the creation of control systems and algorithms that specify how a robot acts in response to sensor data and how it completes tasks. Rule-based systems, machine learning-based systems, or a combination of the two can also be used in these control systems.

5. Programming

Robots are frequently programmed to carry out particular tasks or to adjust their behavior in response to alterations in their environment. The term “programming” can refer to anything from straightforward scripts to intricate software applications that make use of artificial intelligence and machine learning methods.

6. Applications

Applications of robotics can be found in a wide variety of fields, such as manufacturing, healthcare, agriculture, logistics, space exploration, entertainment, and many more. Assembly, surgery, surveillance, and even exploration are just some of the tasks that robots are used for.

7. Autonomy

The creation of robots that can function on their own, including making decisions and carrying out actions without the need for human intervention, is one of the primary objectives of robotics research. Robots that operate entirely on their own can be useful in situations in which the presence of humans would be impractical or dangerous.

8. Human-Robot Interaction

The development of robots that can interact with humans in a way that is both natural and secure is becoming an increasingly important area of research and development as the use of robots in our everyday lives increases. This includes conducting research in fields such as social robotics and human-robot collaboration.

9. Research and Development

The field of robotics is constantly being researched and developed, leading to consistent technological and capability advancements. Researchers and engineers are constantly working to enhance the functionality, productivity, and security of robots.

Robotics is a dynamic and rapidly evolving field that plays a crucial role in modern technology and automation. It offers solutions to a wide range of challenges and tasks in a variety of industries and applications. In general, robotics is an important part of modern technology and automation.

Types of 3D Printers Suitable for Model Making

Many different kinds of 3D printers can be used for model making, and each of these printers has its own set of benefits and drawbacks. Your requirements and available funds should serve as primary considerations when selecting a 3D printer. The following are some common kinds of 3D printers that are used for making models:

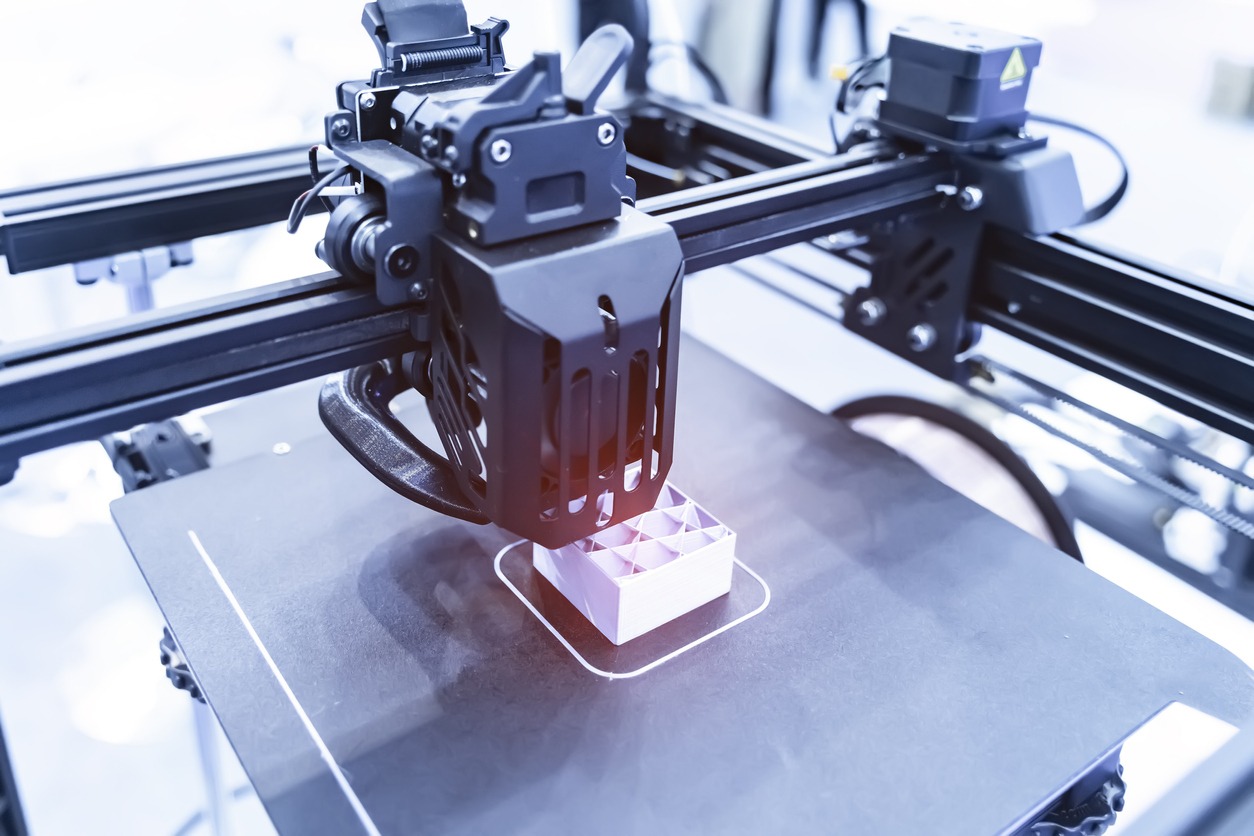

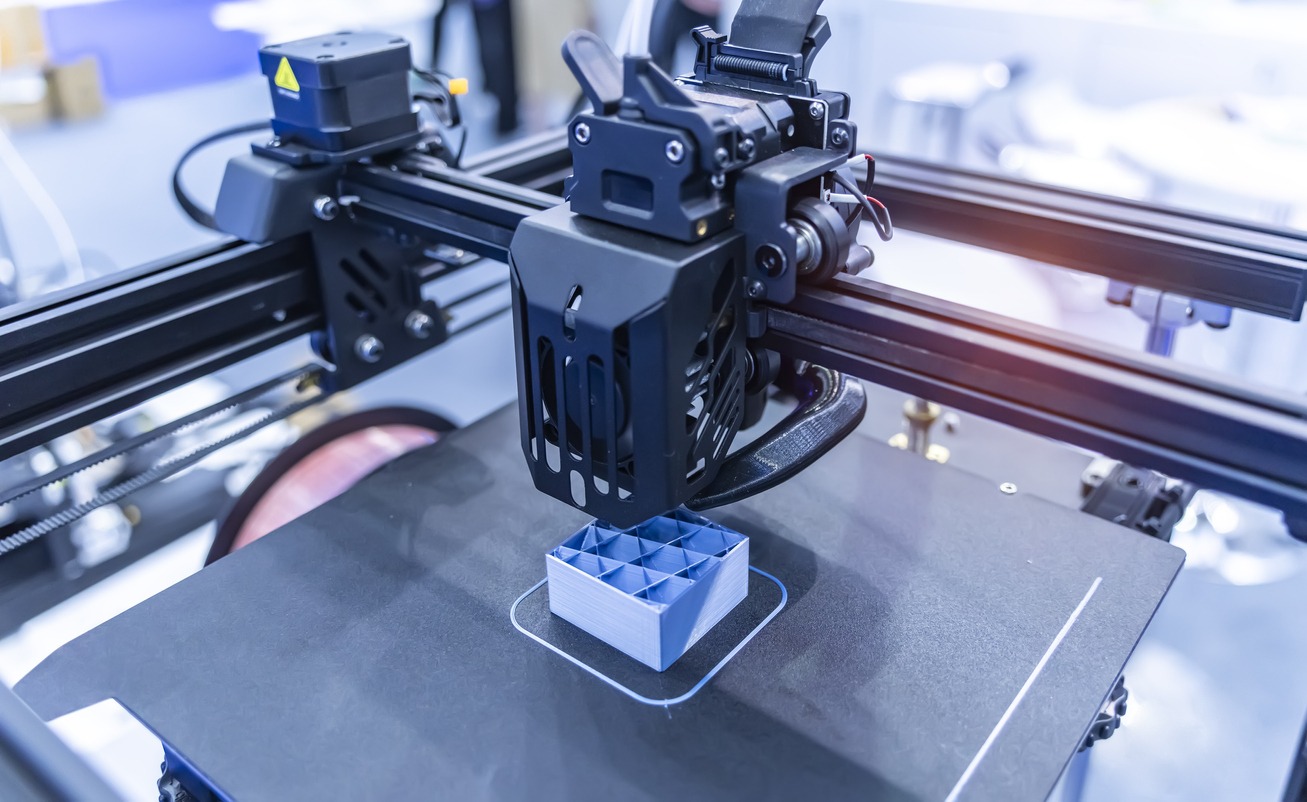

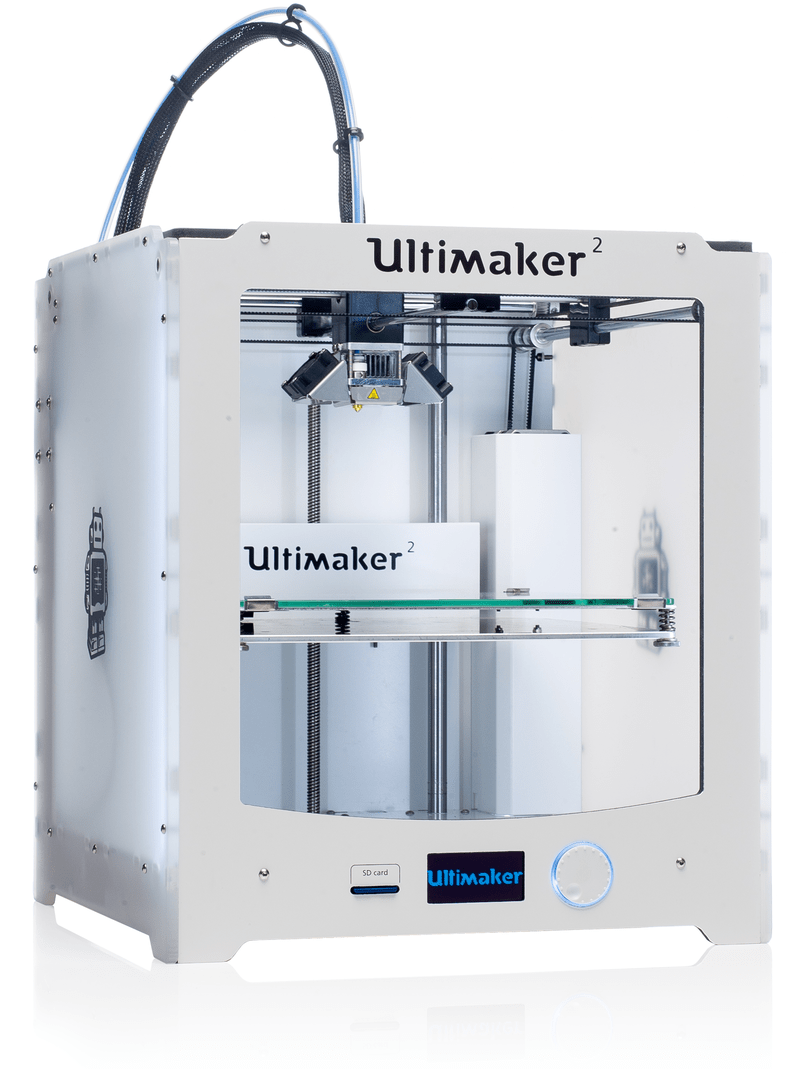

1. Fused Deposition Modeling (FDM) Printers

- Description: FDM printers are some of the most widely used and accessible 3D printers available today. The object is constructed one layer at a time through the process of extruding melted plastic filament.

- Advantages: Materials that are not only inexpensive but also easily accessible and can accommodate a wide variety of model sizes and levels of complexity.

- Limitations: The resolution and surface finish are limited, and there may be a need for post-processing to remove visible layer lines.

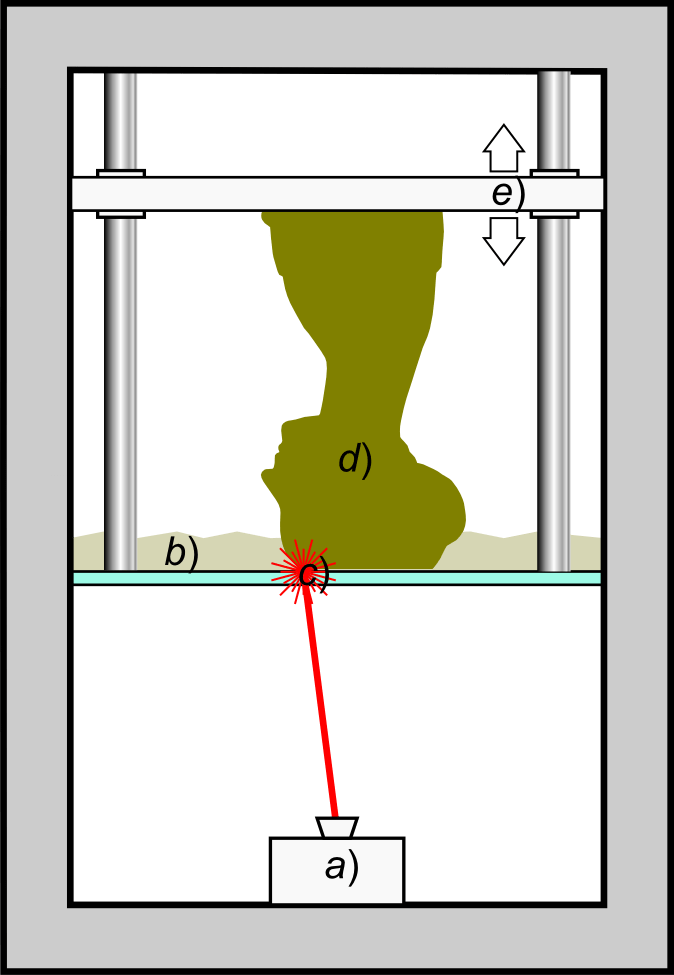

2. Stereolithography (SLA) Printers

- Description: SLA printers employ a UV laser to cure liquid resin layer by layer, thereby producing models that are extraordinarily detailed and accurate.

- Advantages: Models that are intricate and small-scale can benefit from the high resolution and excellent surface finish of this material.

- Limitations: Resin is often more expensive than other materials, and working with resin requires extreme caution and observation of all relevant safety procedures.

3. Digital Light Processing (DLP) Printers

- Description: DLP printers are very similar to SLA printers, with the exception that they cure the resin with a digital light projector. They have quick printing speeds available.

- Advantages: Models that are intricate and detailed will benefit from the model’s high resolution, speed, and accuracy.

- Limitations: Resin handling and cost might be concerned, just like they are with SLA.

4. Selective Laser Sintering (SLS) Printers

- Description: Powdered material, typically nylon, is fused layer by layer by a laser in SLS printers, which results in models that are robust and long-lasting.

- Advantages: There is no requirement for support structures, it is possible to produce functional parts, and a diverse selection of materials can be used.

- Limitations: When compared to SLA and DLP, LCDs typically have a lower resolution and come at a higher cost.

5. PolyJet Printer

- Description: The printing process in PolyJet printers involves the layering and jetting of a liquid photopolymer material that is then cured using ultraviolet light. They can produce models with multiple colors as well as multiple materials.

- Advantages: Printing in a variety of materials and colors, in addition to having a high resolution and an excellent surface finish.

- Limitations: The costs of equipment and materials can be high, and the amount of work involved in maintenance may be greater.

6. Binder Jetting Printers

- Description: Binder jetting printers combine powdered material layer by layer using a liquid binding agent. These printers are suitable for the creation of full-color models.

- Advantages: Quickly create models that are vividly colored and intricately detailed with this tool.

- Limitations: The resolution produced by this method is not guaranteed to be as high as that produced by other methods, and post-processing is frequently necessary.

7. Metal 3D Printers

- Description: Direct Metal Laser Sintering (DMLS) is one type of metal 3D printer. This type of printer uses a laser to sinter metal powder, which enables the creation of metal components.

- Advantages: Ideal for fabricating high-strength and long-lasting components for use in metal model kits.

- Limitations: Expensive, restricted to metal materials only, and may call for facilities with specialized equipment.

When selecting a 3D printer to make models, it is important to take into consideration several factors, including the level of model detail desired, the amount of money available, the amount of space that is available, and so on. Regardless of the 3D printing technology that was utilized, additional post-processing steps, such as sanding, painting, or assembly may be required to achieve the desired finish for your models.

Why Use 3D Printing and Robotics in Model Making?

When it comes to model making, utilizing 3D printing and robotics offers several benefits and opportunities that improve both the process as a whole and the results. The following is a list of some of the primary reasons why these technologies are beneficial in the context of model-making:

1. Precision and Detail

The use of 3D printing enables model components to have extremely high levels of precision and detail. It can be challenging to achieve this level of accuracy using the manual methods that have been used traditionally.

2. Customization

The use of 3D printing makes it possible to personalize models so that they can better fulfill particular design requirements. The makers of models can easily alter the models’ dimensions, shapes, and features to create ones that are one-of-a-kind and customized.

3. Complex Geometries

Printing in three dimensions (also known as 3D printing) enables the production of intricate and complex shapes that would be difficult or impossible to produce using more conventional methods. This is especially helpful when replicating complex vehicle components or architectural elements that require a high level of detail.

4. Prototyping

When it comes to prototyping and testing designs before committing to a final model, 3D printing is an excellent tool to have at your disposal. It enables rapid iteration of models as well as the refinement of existing ones.

5. Scale Models

Because it is possible to print precise scale models with 3D printing, this technology is a useful tool for professionals such as architects and engineers, as well as for hobbyists who need accurate representations of buildings, products, or other objects.

6. Replication

The use of 3D printing makes it possible to make exact copies of valuable or fragile items without putting any strain on the originals. Particularly significant is this point in the disciplines of archaeology and preservation.

7. Reduced Material Waste

The more conventional methods of model-making frequently result in a considerable amount of discarded material. The process of 3D printing is more effective than other manufacturing methods because it typically results in less waste and utilizes the exact quantity of material that is required.

8. Automation and Efficiency

The use of robotics enables model makers to automate a variety of labor-intensive processes, such as sanding, painting, and assembly. This results in an increase in the production process’s efficiency as well as its consistency.

9. Complex Movements

Models can benefit from the addition of robotics’ dynamic and interactive components. For instance, using robotic components, model vehicles can be made to move, and lifelike animations can be created in dioramas using these components.

10. Interactivity

Robotics can give models the ability to react to external stimuli or user inputs by integrating programming and sensors into the system. This may be put to educational use, or it may be utilized in the construction of interactive exhibits.

11. Enhanced Realism

When combined, 3D printing and robotics have the potential to produce extremely lifelike models. For instance, parts that have been printed using a 3D printer can be combined with robotic components to create figurines or moving machinery that appear to be alive.

12. Educational Value

Model-making that makes use of modern technologies such as 3D printing and robotics can be an educational experience for those who participate in it. This provides individuals with the opportunity to learn about contemporary technologies and the uses to which they can be put while pursuing their hobbies.

13. Time Savings

Both 3D printing and robotics have the potential to significantly cut down on the amount of time needed to create intricate models, which in turn paves the way for quicker completion of difficult projects.

The use of 3D printing and robotics has increased the capabilities of model-making, making it possible to achieve levels of precision, customization, and automation that were previously difficult to accomplish. These technologies make model-making more accessible and efficient for professionals, hobbyists, and educators alike, which opens up new creative possibilities.

Applications in Various Types of Models

Both 3D printing and robotics have a wide variety of applications in a variety of model types, which improves the creation of the models as well as their functionality. The following are some examples of how these technologies can be applied in various contexts involving model-making:

1. Scale Models

Architectural Models

The use of 3D printing allows for the creation of architectural models that are extremely detailed and faithfully represent a variety of scales of buildings and landscapes.

Automotive Models

3D printing allows enthusiasts to create scale replicas of vehicles, including automobiles, trucks, and motorcycles, with a high level of accuracy in their detailing.

Aircraft and Aerospace Models

The process of using 3D printing to create realistic models of aircraft and spacecraft is popular among hobbyists and has educational applications as well.

2. Dioramas

Historical Dioramas

Robotics can be used to give historical dioramas a sense of motion by, for example, animating scenes from the past or recreating battles with miniature soldiers.

Natural Landscapes

Both terrain and landscape features can be created with the assistance of 3D printing, while robotics can animate elements such as waterfalls, windmills, or animals found in dioramas.

3. Miniature Figures

Gaming Miniatures

The advent of 3D printing has made it possible to create individualized gaming miniatures, such as characters, monsters, and scenery for use in tabletop games.

Historical Reenactments

In the performance of historical reenactments, miniature figures often stand in for the roles of soldiers, civilians, and the settings in which they lived during different periods.

4. Architectural Models

Conceptual Models

The ability of clients to more effectively visualize projects is made possible by the use of 3D printing by architects, who can create physical prototypes of building designs.

Urban Planning

Printing in three dimensions (or 3D printing) helps models of cities and urban developments convey proposed changes and designs more accurately.

5. Entertainment and Props

Film and TV

Theatrical productions, movies, and television shows can all benefit from the use of 3D printing for the creation of props, costumes, and set pieces.

Cosplay

Intricate costume components and accessories can be fabricated with the help of 3D printing by fans who participate in cosplay events.

6. Educational Models

Science Education

Anatomical models, geological formations, and scientific equipment can all be created with the help of 3D printing for educational purposes.

Robotics Education

To educate students about programming, engineering, and automation, robotics kits and models are frequently utilized in classroom settings.

7. Industrial and Product Design

Prototyping

Before beginning production on a large scale, designers can use 3D printing to quickly prototype their product designs and test various functional aspects.

Product Models

Through the use of 3D printing and robotics to add movement or interactivity, realistic product models can be crafted for marketing and presentation.

8. Medical Models

Anatomical Models

The production of anatomical models for medical training, patient education, and surgical planning can be accomplished through the use of 3D printing.

Prosthetics and Orthotics

Customization of prosthetic limbs and orthotic devices is now possible thanks to the advent of 3D printing.

9. Robotics Models

Robot Prototyping

For research and development, 3D printing can be of assistance in the creation of robot prototypes.

Robotic Demonstrations

Models and kits of robotics are utilized in the context of educational demonstrations as well as to display the capabilities of robots.

10. Art Installations

Interactive Art

To create works of art that are both interactive and dynamic, some artists incorporate 3D printing and robotics into their installations.

In each of these different contexts for making models, 3D printing and robotics offer specific advantages, such as precision, customization, automation, and enhanced realism. These advantages make it possible for hobbyists, professionals, and educators to push the boundaries of both creativity and functionality.

Choosing the Right 3D Printing and Robotics Technologies for Model Making

When selecting the appropriate 3D printing and robotics technologies for model making, it is important to take into consideration your unique requirements, financial constraints, and the level of difficulty of your projects. When deciding which technologies to use, the following are some important considerations to keep in mind:

1. Type of Model

Think about the different kinds of models you want to build. What kind of models are they? Architectural, to scale, dioramas, or something else entirely? Different models may call for various 3D printing and robotics solutions.

2. Resolution and Detail

Methods of high-resolution 3D printing such as SLA and PolyJet are appropriate for the creation of intricate and detailed models, whereas FDM may be adequate for larger-scale projects that require less attention to detail.

3. Material

Find out what kinds of materials you’ll need for your models. Because some 3D printers can only work with certain types of material, you need to make sure that your printer is compatible with the properties you want for the material.

4. Size and Scale

Think about the proportions of the size and scale of your models. Make sure that the 3D printer you choose can handle the dimensions of the models you intend to print.

5. Budget

Determine how much money you are willing to spend on components for both robotics and 3D printing. Because certain technologies and pieces of equipment can be quite pricey, it is important to strike a balance between your financial resources and the objectives of your project.

6. Skill Level

Consider your level of expertise and previous experience with robotics and 3D printing. Certain technologies might call for more advanced levels of knowledge and ability.

7. Speed and Efficiency

Take into consideration the time limits that your projects have. Some methods of 3D printing, such as FDM, are quicker, while others, such as SLA or SLS, may take longer but produce a higher-quality final product.

8. Complexity and Interactivity

Determine whether or not your models require the addition of complex movements or interactive features. Robotic components have the potential to add dynamism to a system but may call for specialized knowledge.

9. Post-Processing Needs

Find out if your models need any post-processing steps like painting, assembly, or additional detailing. Because of this, your choice of 3D printing method may be affected.

10. Safety and Environmental Considerations

When working with materials that are used in 3D printing or incorporating components of robotics, it is especially important to be aware of the necessary safety precautions and environmental considerations.

11. Future Expansion

Think about whether or not you intend to increase the scale of your model-making abilities in the near or distant future. Pick technologies that can adapt to your changing requirements.

12. Availability of Support and Resources

Investigate whether or not the 3D printing and robotics technologies of your choice have access to the necessary levels of technical support, online communities, and resources. Having access to knowledge and assistance in problem-solving can be extremely valuable.

13. Project-Specific Requirements

Determine whether there are any particular project requirements or constraints. For instance, if your model must be able to withstand the elements when used outside, you should choose materials and technologies that are capable of satisfying those requirements.

14. Prototyping vs. Final Models

Make a distinction between the prototyping stage and the model creation stage. While some technologies are more suited to the prototyping and iterative design process, others are more adept at producing finished pieces with a high level of polish.

You will be able to make an educated decision regarding the 3D printing and robotics technologies that most closely align with your model-making goals and the requirements of the project if you give careful consideration to the aforementioned factors. When trying to determine which options are going to be best suited to meet your requirements, it may be beneficial to seek the guidance of professionals or communities that are dedicated to model-making.

Conclusion

3D printing and robotics have rapidly evolved into indispensable precision tools for model makers in a wide variety of industries. These technologies make it possible for enthusiasts, professionals, and educators to create models that are highly detailed, customized, and interactive with an accuracy that was previously unattainable. 3D printing and robotics offer a versatile toolbox that can elevate the art and science of model making in several different ways. These include the creation of intricate scale replicas, the animation of dynamic dioramas, and the prototyping of architectural design concepts. These technologies, as they continue to advance, open up exciting possibilities, making it possible for model makers to push the boundaries of both their creativity and the realism of the projects they are working on.