1. Brief overview of model train electronics

Since many years ago, model railroads have gained enormous popularity, and not just among the younger generation. Although they are a relatively new invention, electronic devices for use with model railroads have been warmly welcomed by the majority of model railroad enthusiasts. Any model railroad, from a basic circle of single track to a sizable and sophisticated layout, may benefit immensely from the addition of certain electronic circuits. Some easy electronic projects may give a layout considerably more realism and make the user’s experience much more enjoyable.

An electrical current from a wall socket is used to power a model train by passing it down its rails, wheels, and motor. The train moves when the motor rotates a screw and gear that turn the axel. The track for the model train functions and seems just like a genuine train track.

One electrical current in each rail of the train track is positive and the other is negative. An electrical signal is sent from the controller to the train’s motor when it is energized, which causes the wheels to move. The circuit is finished on the opposing rail, where power returns to the controller to close the circuit.

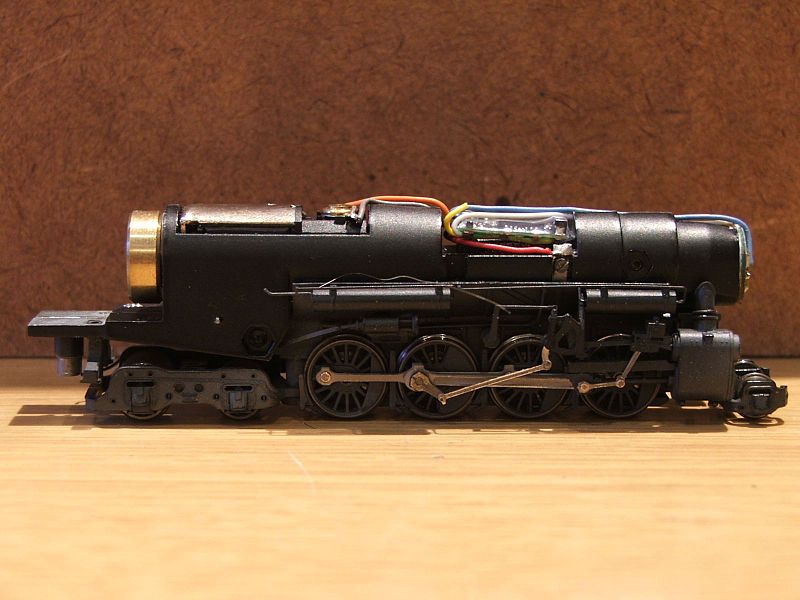

Digital Control (DCC) models are among the most contemporary styles. Each locomotive in this configuration has a little computer inside that the controller may connect to via the power signals on the track. This enables the operator to manage every train independently depending on its parameters.

2. The Basics of DCC Decoders

What is a DCC Decoder?

In contrast to an outdated rheostat-based power pack, digital command control allows for more realistic management of locomotives and, by extension, trains. A system to run model railroads digitally must adhere to the DCC standard. Locomotives on the same electrical piece of track can be independently operated if they have Digital Command Control (DCC).

The National Model Railroad Association’s (NMRA) Digital Command Control Working group developed the DCC protocol. Since the NMRA has trademarked the word DCC, even though it is occasionally used to refer to any digital model railway control system, in actuality, it only refers to NMRA DCC.

In model trains, DCC decoders are electrical components that let them to accept digital orders from a DCC controller like the ECoS. They may be with any DCC-compliant system, such as the ESU ECoS, as they are made to work with different DCC systems. DCC decoders are available in a range of styles and feature sets and come in two primary categories: mobile and stationary.

Mobile decoders are mounted which controls for locomotive speed, direction, illumination, and sound effects are a few typical features. Programmable acceleration and deceleration rates, different lighting settings, and other capabilities are also available in DCC decoders.

Turnouts and signals can be managed by stationary decoders, among other accessories. Digital commands are often sent to DCC decoders as data packets that are sent across the model railroad’s tracks. The data is subsequently interpreted by the decoder, which converts it into actions like adjusting the locomotive’s speed or direction. The concept of command control is straightforward. There is a constant power level on the track, and the train has a decoder in the engine, so you don’t need voltage and polarity to run your train. The receiver receives signals from the throttle and interprets them as commands for direction and speed. The decoder ignores any signals that are not tuned in to receive them, just like a television. This eliminates the need for significant switch banks and enables the modeler to operate a variety of trains on the layout.

The DCC decoder selected must, however, be compatible with the precise locomotive or piece of rolling stock that it will be installed in. The improper DCC decoder might cause the locomotive to function poorly or even cause damage because some of them are made for certain scales or types of locomotives.

In contrast to conventional DC control, which uses the voltage on the rails to determine a locomotive’s speed and direction, DCC delivers individual trains a steady stream of data. Since every locomotive and accessory has a decoder that reacts to this information, it is possible to precisely operate many trains on the same track at once.

DCC has made things better for model railroads. In DCC, the direction and speed of each locomotive are conveyed as digital signals included within the electrical signals moving around the track, but the power to the motor is still provided via the rails at a constant level. Each DCC loco includes an internal minicomputer that monitors certain messages and runs the motor in accordance with the commands.

DCC decoders provide a lot of flexibility and control for model railroaders, and they are a crucial part of a contemporary digital model railroad system. Understanding the operation of DCC is crucial for properly appreciating its benefits. The main elements and procedures for running model trains using DCC are described here:

Central command station. The Central Command Station is the brain of a DCC system. To connect with locomotive decoders, this machine creates digital control signals that are transmitted across the rails. You may usually change the speed and direction of your trains using the throttle control found at the Central Command Station.

Locomotive decoders. A decoder is required for every locomotive on your layout that you want to use DCC to control. The Central Command Station sends digital signals, which these tiny electronic gadgets mounted within the train receive and decode. Decoders manage a number of operations, including sound effects, motor speed, and direction.

Electronic addresses. A distinctive digital address, normally ranging from 1 to 127, is given to each locomotive decoder. The Central Command Station transmits orders to the decoder of a specific locomotive when you pick its address on the throttle control to operate it.

Monitor bus. The electrical infrastructure that supplies the tracks with electricity and digital signals is known as the track bus. DCC utilizes a single continuous voltage on the rails as opposed to DC systems, which call for intricate block cabling to separate different tracks. This voltage is topped by digital signals, which enable accurate operation of several locomotives on the same track.

Function outputs. Decoders frequently contain function outputs that may operate auxiliary features like headlights, horn sounds, bell sounds, and even smoke generators in addition to managing speed and direction. These outputs can be set up to respond to particular instructions or events on your layout by activating.

How DCC decoders differ from traditional control systems

There are several compelling differences between DCC decoders to traditional control systems:

Streamlined Wiring. To operate several trains and separate various track segments, DC control systems need intricate wiring. By enabling you to power the whole layout with a single, consistent voltage and doing away with blocks and toggle switches, DCC makes wiring simpler.

Operation of several trains. DCC eliminates the requirement for segregated blocks so that numerous trains can operate on the same track. Because each locomotive reacts to its specific digital address, you have total control over how each train moves.

Automation and function. Beyond direction and speed, DCC decoders may also operate lights, smoke generators, and even couplers. By doing so, a number of layout-related tasks can be automated which will improve user experience.

Upgrades and expansion. DCC systems may be expanded quite easily. As your budget and layout change, you may start with a simple setup and progressively add additional locomotives and extras. DCC can be scaled, which makes it a long-term investment.

Understanding the Functions of DCC Decoders

The track layout’s locomotives are each outfitted with a specially addressed DCC mobile decoder. The operator may change the speed, direction, illumination, and other characteristics of any locomotive on the track by selecting it by address and using a throttle. DCC enables numerous throttles to simultaneously operate several locomotives. Locomotive settings are maintained for unselected locomotives. How many locomotives can operate at once on your layout depends on the make and model of a given command station.

A power circuit in the DCC decoder transforms the DCC power signal into DC power for the motor and lights. Additionally, the decoder incorporates digital logic for controlling the locomotive using the data from the power signal.

Speed control

In a DCC system, the operator’s throttle connects digitally to the decoder, and the speed of a train is defined by DCC as a “speed step” ranging from zero (stopped) to 126 (100% speed). Turning a throttle knob by the operator causes the throttle to translate this into a speed step and transmit it to the decoder.

The decoder only deals with a percentage of track voltage, commonly stated as a number from 0 to 255 (where 255 = 100%), even though the motor controller chip on the DCC decoder works with the motor in terms of a PWM pulse length and the delay.

When two or more locomotives don’t accelerate, decelerate, or operate at the same speed for the speed step the throttle is set to, there are a number of ways to combine them. The locomotive’s performance should be adjusted so that the push-pull impact of a speed discrepancy is all but eliminated. Configuration Variable (CV) programming for locomotive DCC decoders is the solution.

When used by the manufacturer, several of the suggested and optional CVs enable the opportunity to fine-tune certain speed parameters.

If the locomotive decoders are made of high-quality decoders, they should come with multiple mechanisms for adjusting the locomotives to operate at about comparable speeds over the whole speed range. One or more of the following must be configured in order to activate these methods:

- CV2- Allows for changing of the start voltage.

- CV3- Adjustment of acceleration rate is made possible with.

- CV4- Allows for adjusting the deceleration rate.

- CV5- The top voltage (the maximum voltage from the decoder to the motor) may be adjusted.

- CV6 – Enables voltage modification at the mid-speed step.

- CV23- To mimic different train loads in consists, attenuates acceleration in combination with CV3.

- CV24- To mimic different train loads in consists, attenuates deceleration in combination with CV4.

- CV25 – Chooses one of 126 factory-preset alternative speed tables.

- CV29- When enabled, enables the manually configured speed table (CV 65 – 95) ++

- CV65- Users of manual speed tables can specify additional voltage provided between the stop and speed step 1 using its kick start feature.

- CV66 – Forward Trim modifies the applied voltage in the forward direction as a percentage of the supplied value.

- CV67-94- Has a value that determines the speed at each of the 28 speed increments. (Step 1 for CV67, Step 28 for CV94)

- CV95 – Reverse Trim modifies the applied voltage in reverse as a percentage of the given value.

Direction control

“Forward” with DCC always refers to the loco’s front. A DCC loco that is traveling away from you may be turned and placed back down so that it is now heading in the other direction. The loco will operate as previously if the rails’ “polarity” (really, phase, as DCC is a kind of AC) is reversed. With DCC, polarity/phase are irrelevant. A DCC instruction to switch a loco’s direction from “forward” to “reverse” is addressed to the loco, which the decoder then receives and acts upon by altering the DC polarity it feeds to the motor, changing the loco’s direction of motion.

Lighting and sound effects

DCC’s lighting capabilities are quite potent and need to be fully utilized. For good reason, LED lights have taken over as the preferred option for most modelers. Compared to incandescent lights, they are brighter. They will outlast incandescent lights by thousands of hours. Compared to incandescent lights, they run at a substantially lower temperature. Most importantly, compared to incandescent lamps, LEDs are really considerably simpler to install on DCC-equipped locomotives, rolling stock, and layouts.

LEDs are linked to a function output in model railroading, notably DCC decoder installations, to allow on/off control and to offer unique lighting effects to locomotives and rolling stock that were previously nearly unattainable. Here are some of the advantages of LED lighting over incandescent lighting

- No discernible fluctuations in LED brightness with shifting layouts or systems that result in different track voltages, but incandescent lights can fluctuate from extremely dim to brilliant and even blow.

- No heat, as opposed to incandescent lights that may warp plastic bodies.

- A voltage reducing resistor just has to be 1,000 Ohms in value, however incandescent lights call for you to “calculate” a value.

- Later SMD LEDs are really simple to install—just attach them to the light lens.

- LEDs offer a greater brightness and a longer lifespan.

Adding scale-appropriate sound effects to a layout is one of the best ways to make it more engaging. These can include not just the apparent noises made by locomotives and railcars, as well as whistles, horns, and brakes, but also background noises like birds, stream water running, city traffic, or even a distant sawmill.

Sound effects are one of the most well-liked applications for DCC. In order to replicate authentic sounds like engine noises, horns, and bells, sound decoders can be fitted in locomotives. By bringing the layout to life and enhancing the realism of the scene, these sound effects may significantly improve the entire experience of running a model train.

For modelers and railroaders, a range of various sound accessories are available in addition to sound decoders. These include speakers that may be set on the layout or fitted in locomotives to produce background noises like birds tweeting or city noises. Additionally, there are sound modules that may provide specialized sound effects for scenarios or activities, such a crossing gate warning or a train whistle.

Sound decoders are offered by certain manufacturers. These decoders play locomotive sounds through a tiny audio speaker in addition to performing all the regular DCC locomotive control operations. Diesel locomotives emit a hum from their engines that varies in pitch depending on engine speed. Steam locomotives make the distinctive chuff noises while traveling at the proper speeds. Both the brakes and the valves hiss. Programmable sound tables are a characteristic of high-end sound decoders. Users of high-end sound decoders can alter the sounds that are produced by their locomotives using a computer that is fitted with specialized sound decoder programming software and connected to the DCC controller.

The term “scale sound” describes the variations in sounds you should hear when connected to various scales. The noises employed for a N scale layout, for instance, should be much quieter than those for an O scale configuration. Your sound is “out of scale” if it is too loud for N scale, just like an O scale building would be on a N scale plan.

The main factor affecting scale sound is loudness, however it’s vital to keep in mind that the human ear can only distinguish midrange tones when the level is low. Higher frequency sounds and the low frequency bass might be missed. Even at low volumes, there are certain techniques to boost these frequencies. For instance, many compact stereo systems have “bass boost” knobs that are specifically for such use.

For more tips on building your first model train click this:

https://myhobbylife.com/building-your-first-model-train-tips-and-tricks/

3. Why Use DCC Decoders in Model Trains?

Advantages over analog systems

Every modeler, from the beginners to the expert, and every layout, from the tiniest to the biggest, may benefit from DCC. Once the fundamental system is in place, the modeler can choose how much of the capability is available and may expand the system as the layout changes. New features can be added as the equipment currently used goes along. The decoders you install in the locomotives are frequently where the most effort and money are spent. These are system-upward compatible as the trail grows and adds to it. More sophisticated system can be developed at comfortable speed and as the budget allows by simply adding more components.

Most home designs are compact or medium-sized. They often only have a little length of track available for analog block control; in these circumstances, DCC offers a significant benefit. You can run more locomotives in a smaller space as blocking is not necessary. With each train operating on its own, operation is far more interesting. Banking or double heading may be utilized to match the speeds of locomotives made by various companies. A locomotive’s highest speed restriction can be set or realistic acceleration and deceleration rates can be implemented.

DCC enables authentic operation and no wiring problems for the big home or club layout. The inside loop running counterclockwise and the outside loop running clockwise all day is not very thrilling; layouts operated with DCC may operate more than 2 or 3 trains at once. The simplicity of wiring makes connection easy and speeds up the start-up of operational sessions.

The ability to operate individual locomotives wherever they are on the layout is a major benefit of digital control. When using analog control, it is necessary to connect the track into distinct “blocks” with switches on each one to operate more than one locomotive separately. Anywhere they are, locomotives can be controlled via digital control.

The “inertia” simulation feature, which allows the locomotive to realistically increase or reduce speed gradually, is frequently included in digital locomotive decoders. Many decoders also continuously modify motor power to keep speed steady. Most digital controllers allow an operator to set the speed of one locomotive and then select another locomotive to control its speed while the previous locomotive maintains its speed. Wiring requirements are generally reduced compared to a conventional DC powered layout.

Wiring requirements are generally reduced compared to a conventional DC powered layout. When accessories are controlled digitally, wiring is routed to accessory decoders rather of being linked to each one separately by a central control panel. Since just the digital signal and any auxiliary power supply require cross baseboard joins, this can significantly minimize the amount of inter-board connections for portable layouts.

On-board sound modules for locomotives as small as N scale have recently been developed, thanks to improvements in smartphones, which frequently feature discreet yet high-quality speakers. One example of the expanding list of features you may use is the inclusion of sound or computer control. Your railroad may be as straightforward or intricate as you choose. Above all, DCC makes it possible to operate your trains just like the original.

Customization options

The locomotives’ decoders may each be customized to have a different personality. When DCC decoders are programmed, the command station delivers programming data to the decoders, who then store it for later use. To program decoders, the locomotive does not need to be opened. It can be prepared to go with only a few keystrokes. Each decoder can have a distinct personality, and until its programming is altered, it “remembers” it. The decoders’ numerous working properties are set using configuration variables, or “CVs.”

The functions available for DCC decoders are numerous. There are many feature combinations and pricing points available because not all features are significant to everyone. An overview of the majority of the features present in modern decoders is provided below. To ensure that the decoder you are purchasing has the functions that are crucial to you, check with the manufacturer. You don’t have to use the same decoder in every locomotive since DCC decoders are compatible.

Locomotive Address. A specific decoder is given a two-digit (CV01) or four-digit (CV17 & 18) number known as the locomotive address. To access the locomotive in your system, dial this number. While some systems substitute colors for numbers, in practice these colors correlate to numerals.

Locomotive Speed Controls. Because DCC is a digital system, locomotive speeds are determined by discrete speed increments. For speed control, the DCC standard specifies 14 steps in each direction. Some decoders provide sophisticated 28-step processing for even more speed control. How about 128 step operation, if that isn’t enough? You may regulate your speed very precisely with 128 step operation. You have the power to make those trains crawl! Depending on the throttle you are using, you may be able to benefit from additional speed steps. The maker of a given decoder decides how many speed steps it can employ; some systems use CV29 to configure the decoder’s operating mode.

Speed Stabilization or Back EMF Speed Control. This is the locomotives’ cruise control. It is also known as load adjustment, and it is a function of some decoders that allows you to select a speed for your locomotive and have it operated at that rate “uphill and down dale.” When 128-speed step control is not available, this is very helpful for low-speed operation. You may choose how much of this impact your system will use with any locomotive by using decoders that provide scalable speed stabilization. With this kind of speed stabilization, you may avoid the “pushy pusher” issue that was present in non-scalable back emf decoder versions. Due to the ongoing stabilization in this scenario, trains running up gradients frequently produced the “concertina” effect while using speed stabilized rear end assistance.

Acceleration & Deceleration Rates. When a new increase speed order is received, the decoder will accelerate to go from one speed step to the next. You may adjust the acceleration rate (CV03) to approximate train weight. The pace at which the decoder reduces speed in response to a new decrease speed command is known as deceleration. To imitate inertia, utilize the deceleration rate (CV04). You may program your locomotives to start slowly due to a high load and to take a long time to stop due to the inertia of the train once it is rolling, much like the prototype.

The Throttle Response Curve. It’s simple to mix acceleration and deceleration with the throttle response curve. The relationship between the motor voltage (throttle setting) and the speed step instruction transmitted by the command station is known as the throttle response curve. The rate of change from one speed step to the next up or down is known as acceleration or deceleration.

3.1 The Impact of DCC Decoders on Model Train Experience

Realism and control

Enhanced realism. More realistic train operations are possible with DCC. Each locomotive has autonomous controls for its speed, direction, and even its sound and lighting effects. Model trains layout comes to life with this degree of control, making it more engaging and fun.

Realistic sound and lighting. Many locomotives with DCC include built-in lighting and sound features. As a result, distinctive sounds of various locomotives can be duplicated and different lighting elements can be managed, which gives the layout an additional depth of realism.

Precision control. DCC enables distinct speed and direction settings for each train, allowing for fine control of locomotives. The realism and operating experience of the layout are improved by this level of control.

Simultaneous operation. Many trains can be operated on the same track at once, thanks to DCC. Because each locomotive has an own digital address, each train can completely operate interruption.

Scalability and future-proofing

Any scale and gauge may use DCC as long as the locomotives can accommodate a decoder. With connectors, sockets, and harness wires to accommodate various applications, decoders are available in a variety of sizes and forms. jobs for O gauge and bigger scales range from the smallest to the largest and highest current. Z gauge models are among the many applications for which there is a decoder. It’s crucial to understand that they all perform the same basic function, and harness wire colors are uniformly used. Until you get comfortable with decoders, always seek guidance on appropriate ones.

It might be difficult to select a system in the ever-changing world of technology that will continue to be useful, efficient, and successful over time. It must anticipate and adapt to changes in user demands and technical improvements in order to be future-proof. By taking proactive measures, the system is kept flexible and scalable as it develops.

Scalability is the system’s capacity to manage growing data volumes, user traffic, and load levels without compromising performance or user experience. A scalable design guarantees that your software can manage the increasing load without crashing as your user base grows or the demands on your application rise.

To be competitive and relevant in the ever-changing model railroad industry, the system must be future-proofed using scalable and adaptive design concepts. DCC may easily change to suit user needs, embrace new technologies, and handle expansion by anticipating scaling requirements and building for flexibility.

DCC is designed to control model railroads more realistically and with fewer operational restrictions. Driving in miniature is as near to actual driving as you can get!