Whether you do periodic maintenance tasks around the house or work at a mechanical garage, you’re no stranger to a toolbox; they come in different sizes, shapes, designs, and materials.

This variety of features can be overwhelming sometimes, making it difficult for people to choose the right toolbox. However, it doesn’t have to be that way. All you have to do is to consider your needs and factors like toolbox capacity, material, and price to make the right decisions.

This guide to tool boxes aims to make the selection process easier for you. But before that, let’s take a look at a few reasons why having a toolbox is essential.

Why is a toolbox Important?

- A Toolbox helps you store and organize your tools. Without a toolbox, more time is wasted as people look around for the tool they need.

- Your tools are at a greater risk of getting damaged without a toolbox. For example, an electronic multimeter is much safer inside a well-kept toolbox than just lying around.

- A Toolbox also makes it less likely for your tools to get lost or stolen. Collecting high-quality tools might take a long time and a lot of money. Having a toolbox can keep them secure from theft.

- Tool boxes bring much-needed portability for DIY and home use. They allow us to store tools in a compact place and carry them conveniently.

Before moving forward, let us explain the difference between “toolbox” and “tool chest.” Even though these terms are used interchangeably, they mean different things when buying a toolbox.

Tool boxes

A toolbox refers to a small hand-carry, usually made of plastic, that stores fewer tools. It is the most common type of tool storage for DIY use.

Tool Chests

A tool chest refers to a tool storage option that features drawers and cabinets. They are bigger and usually used by professionals. They are made of durable materials like stainless steel or aluminum.

Size and Capacity

Size and capacity are the most important factors to consider when buying a toolbox. If your toolbox has sufficient space, you’ll not only be able to store your tools, but it’ll also be much easier to keep them organized.

The first thing to do when choosing the right size is to take an inventory of the tools you want to store. When you have a clear idea of how many tools you have, there’ll be little room for errors when choosing the size.

However, you should go beyond that if you want your toolbox to last longer. Ideally, you should choose a toolbox that is able to store your current tools while also leaving some extra space for future tools.

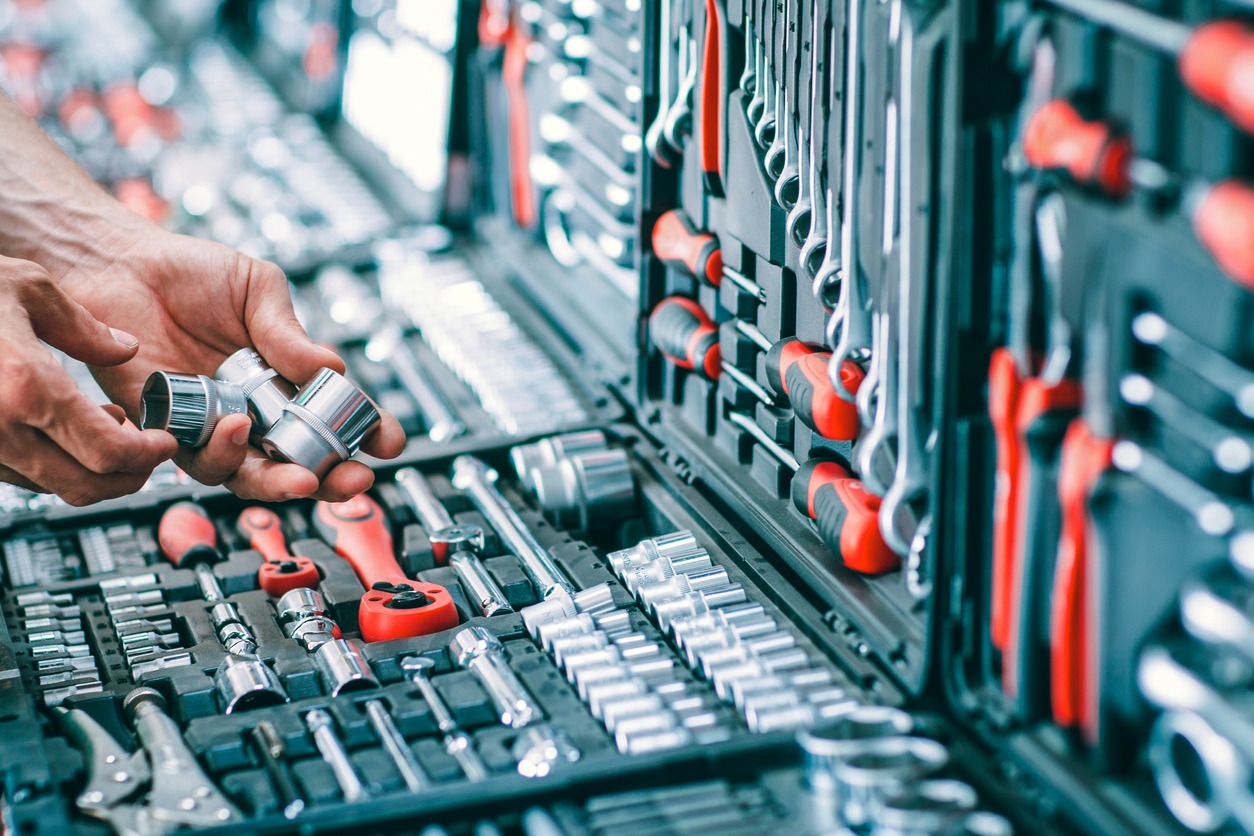

There is a huge variety of toolboxes out there based on the capacity they offer. For example, heavy-duty tool boxes with drawers can store many tools. Similarly, some tool chests have dividers that can store your power and DIY tools separately. On the other hand, most DIY tool boxes are small, light, and portable.

Here’s a breakdown of the fundamental tool chest types based on size and capacity.

Types of Tool boxes (based on Capacity)

Portable Tool boxes

A portable toolbox is the most popular type for DIYers and homeowners. They are small in size and designed to be carried in hand. They provide a high level of convenience as they are easy to store in small spaces and carry around in vehicles. They are also considerably lightweight, making them easy to use.

Apart from the primary storage compartments, these tools also have small spaces to store nuts, small screwdrivers, and nails. They are usually made from metal, plastic, or wood. These tool boxes vary in size and design, and some of the most common types are:

- Cantilever toolbox

- Plastic toolbox

- Tote toolbox

Stationary Tool Chests

A portable toolbox is small enough to carry in hand. You’ll find that we have listed tool chests with wheels under “stationary tool chests.” That is because even though they have wheels, they’re not portable in the DIY sense of the word.

Stationary tool chests are primarily preferred in workshops and garages. They are ideal for storing moderate to heavy power tools. Some of these chests feature drawers and cabinets to provide ample space.

They are big, heavy, and not made to be moved around often. The purpose of caster wheels on these tool chests is to give them enough portability to move easily across the floor. Unlike portable tool boxes, they are not made to carry in hand or vehicles frequently. They are usually kept in a dedicated place in a workshop.

Here are some of the most common types of stationary tool chests:

- Small stationary tool chests (3-5 drawers)

- Rolling tool chests with drawers and cabinets

- Rolling tool chests with drawers and workbench

- Small-size rolling tool chests (3-5 drawers with caster wheels)

Wall-mounted Tool Chests

Wall-mounted tool cabinets, also known as hanging cabinets, are perfect for places with limited floor space. Many workshops use these in addition to stationary tool chests to increase their tool storage space. They also free up ground space for other uses, like installing workbenches.

Hanging cabinets are available pre-made in different sizes, and you can also get them designed based on your requirements. Professionals like mechanics and carpenters also install them in their vehicles to have easy access to their tools wherever they go.

Materials, Strength, and Durability

Let us now look at different tool chest types based on the material, strength, and durability.

Steel Tool Boxes and Chests

Steel tool boxes and chests are one of the most popular choices. These tool boxes have a shiny appearance and are very resistant to stress and blunt force. However, they can lose their protective powder coating and accumulate rust with time. They can deteriorate quicker if placed in harsh weather conditions like rain and humid weather.

They are available in different types and sizes, such as hand-carry cantilever tool boxes or rolling tool chests.

Aluminum Tool Boxes

Aluminum is a relatively durable and robust material tool owners prefer because it’s lightweight and fairly resistant to external elements. Aluminum is significantly lighter than steel and has excellent corrosion resistance, thanks to a thin layer of aluminum oxide that forms over it.

However, it can corrode quickly when exposed to corrosive agents consistently. For added protection, these tool boxes are also coated with protective materials such as paint, lacquer, or anodization. Aluminum is not as thick as steel, but it provides dependable safety for your tools, especially in comparison to plastic.

Plastic Tool boxes

Plastic is the most common material for hand-carry and DIY tool boxes. Even though it is less durable than steel or aluminum, its light weight makes it an easy choice for people looking to store a small number of tools.

Plastic tool boxes also offer better resistance against moisture and other harsh weather conditions. They are quite cheap in comparison to the materials listed above. However, plastic gets scratched more easily, making it harder to maintain a clean and new look. It is perfect for people who want an economical solution to their tool-storage needs.

Locking System

A tool chest goes beyond merely providing you space to store your tools. If the budget allows it, investing in a toolbox with some locking capability is better. This becomes essential when you’re working with expensive and professional tools.

Here are some ways toolbox manufacturers add locking capability to their products:

- Center Key Lock

- Padlock Eye

- Lockable Compartments

- Lockable Drawers

Budget

Price is one of the most important considerations, but you should never choose the cheapest option. A cheap toolbox can do more harm than good. For example, you might end up with a broken or damaged tool chest in a matter of weeks. Similarly, a cheaper alternative is less secure. Saving a bit on your toolbox can cost a lot if your tools get stolen or damaged.

Once you have decided about requirements such as tool chest capacity, material, style, and brand, you’ll find it easier to settle on a price. Generally, the cheapest tool boxes are available for about $25-30. They are small, made of cheap plastic, and break easily.

As you increase your budget to $100, you’ll find more durable tool boxes made of high-quality plastic or even metal (small sized). These also have better features like trays, drawers, and lock eyes. They are best suited for DIY use.

High-end tool chests made for professional use can cost in thousands of dollars. They offer the most space and durability you can find. Tool chests like rolling trolleys and hanging cabinets fall under this category.

FAQs

1. Do I need a big toolbox with a lot of space or a smaller and portable one?

Choosing a toolbox is a subjective matter. Before deciding on a toolbox size, you should take inventory of the tools you need to store into consideration.

If you’re a homeowner or a DIYer, a hand-carry toolbox will suffice for your tool storage needs. On the other hand, professionals like mechanics, carpenters, and plumbers need to have a tool chest with rollers.

2. Why should I consider tool boxes with locks?

If you’re working with expensive tools, investing in a toolbox with a lock is the safer thing to do. These tools can include special-purpose tools, power tools, and tools that are not part of a DIYers toolbox.

3. What are some of the essential tools to add to a toolbox?

Here are some essential tools every tool chest needs to have:

- Hammer

- Adjustable wrench

- Set of screwdrivers

- Hand saw

- Tape measure

- Set of pliers

- Utility knife

- Tape measure

Final Words

Assembling a home toolkit can have many benefits. It can protect your tools from damage and theft, keep them all in one place, and bring convenience. Here are a few fundamental suggestions to keep in mind when choosing a toolbox:

- It is always better to go for extra space.

- It is better to get a toolbox with a locking capability.

- Choose a metallic toolbox over a plastic one if possible.

All of these suggestions are subject to your budget. However, a toolbox can last a lifetime if you treat it like a one-time investment. Stick to the basics, and you’ll find the process of choosing the right tool chest much easier.