We need our cutting tools ready when we are in a hurry to get work done. There is usually no time to stop and sharpen cutting tools in such situations. That’s why we have to keep them maintained and sharp; so that the tools are ready when we need them. Properly maintained and sharpened tools help us finish work faster and more easily. Although the best time to do the maintenance work is right after using a cutting tool, some prefer doing it right before use or whenever they get some free time.

Sharpening vs. Honing

This guide focuses on how to keep your cutting tools maintained and ready for work. However, it’s worth mentioning the difference between sharpening and honing as many people use these terms interchangeably.

Sharpening can be defined as creating a sharp edge on a cutting tool by grinding with a material harder than material of the tool itself. Granite and sandstones have been used to sharpen tools for centuries, while grinding wheels and flat sharpening stones are also widely used to create a sharp edge.

Honing, on the other hand, is like truing and involves straightening out the edge of the blade that might already be quite sharp. Honing is done to create a precise surface through the use of a honing stone. This is an abrasive stone and quite similar to grinding wheels, but more friable and softer. This allows the honing stone to conform and wear in accordance to the shape of the tool.

Understanding the difference between sharpening and honing

Sharpening is more like everyday maintenance of a cutting tool, while honing involves preparing/maintaining an edge that’s already sharp (but not to the professional eyes). Honing helps polish out marks or imperfections due to usage, while sharpening is mostly about keeping the tool ready for work. Regular honing keeps the edge straight–as a result, sharpening is needed less often.

Wide Edge and Burr

These are the other two main phenomena related to sharpening and maintaining tools that have a sharp edge. Burr refers to the small metal piece that is created at the tip of the edge after sharpening (on the grind’s opposite side). A raised burr indicates a thin-enough edge and signals that you should start sharpening the other side. No burr means you have not sharpened the blade properly, while a large burr means you have been applying too much pressure using the stone/grinding wheels.

Wire edge is the round metal wire you see when sharpening the blade, but you might not see it when using whetstones or wetstones. The wire edge starts as a large bur until you polish it down, especially when sharpening thin blades. The sharpening process starts with creating a burr after which you can see a wire edge, which looks pretty sharp, but you still need more work to clean and properly sharpen the blade. The wire edge is prone to chipping, so you’ll have to switch between finer abrasives until it is properly polished.

Sharpening Stones and Angles

Artificial whetstones (also known as wetstones, but that has nothing to do with being wet) work better than natural stones as they usually have two sides (one with a coarser and the other with a finer grit). You can also use bench blocks (can be installed on a bench) or pocket stones, which are portable but can make it difficult to maintain consistent pressure and angle (especially when sharpening long blades). Coarser grits are used for the rapid removal of large amounts of metal and when you want to restore a damaged edge. Finer grits make it easier to refine the edge and remove minor imperfections and scratches.

The sharpness of a blade is directly related to the sharpening angle i.e. smaller angle equals a sharper edge. However, a very small sharpening angle also means less field durability and is not suitable for all tools. A sharpening angle of 10-degrees per side is fine for a knife, but other durable tools such as an ax, machete or draw knife needs an angle of 25 to 30 degrees.

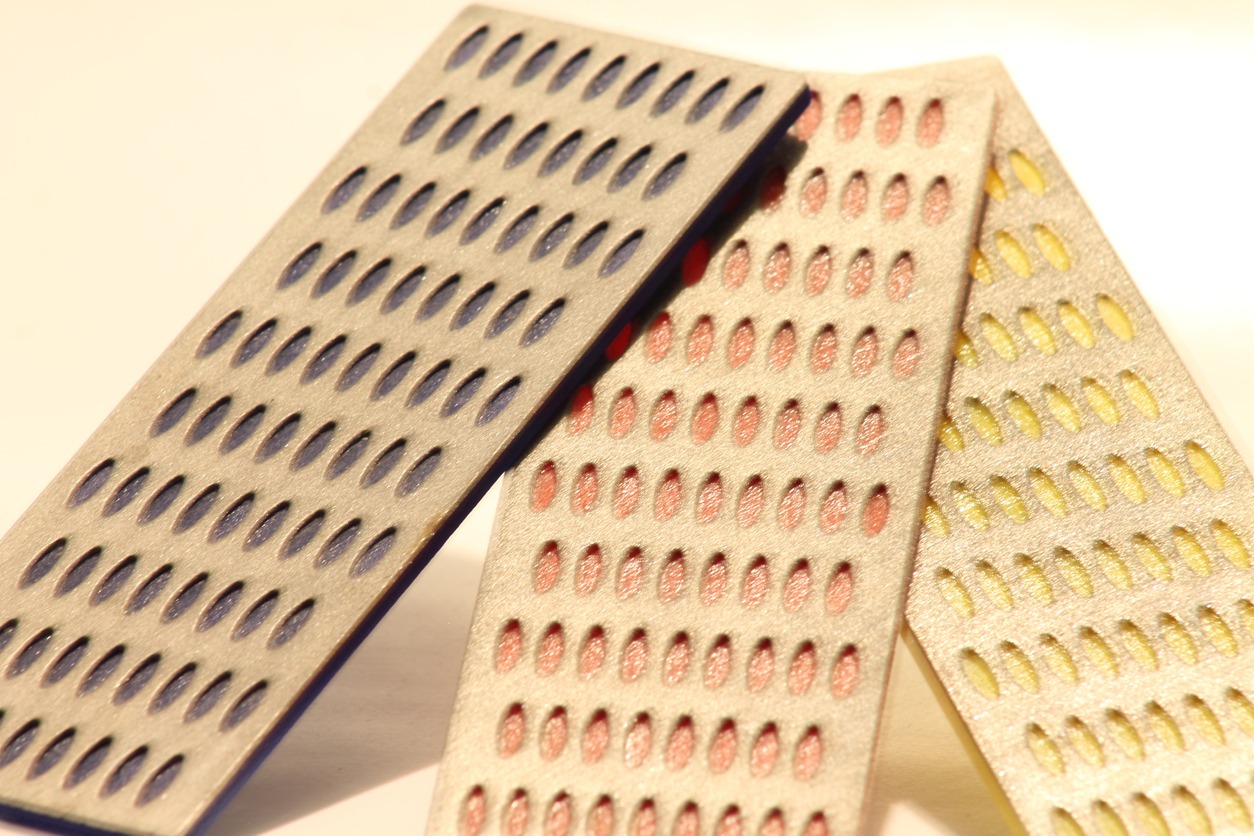

Types of Stones

Sharpening stones are made using different materials and each produces different results. The most commonly used whetstone types include water and oil stones, ceramic stones, and finally the diamond stones.

Water and Oil Whetstones

Water stones are perhaps the most popular of all whetstones and only require water to lubricate the stone while sharpening blades. They eliminate the mess associated with using oil and other lubricants and work best if soaked in water 5-10 minutes before sharpening. Water stones are recommended for home users who want to sharpen their tools quickly without creating a mess.

As the name suggests, these oil stones need oil as a lubricant. Although they take more time to sharpen a blade and using oils can create a mess, they do create a sharper and more polished edge than water stones. Oil stones work well for people who want beautifully polished sharp edges and don’t mind spending some extra time or dealing with oil.

Ceramic Stones

Ceramic stones do not require water or oil and have a very hard surface, which means they’ll keep shape in the long run and last for a long time. However, they can easily break if dropped so you have to be careful when moving ceramic stones around. They are recommended for people such as cooks who work in small spaces and usually don’t have time to deal with water or oil lubrication.

Diamond Stones

Made using industry-type diamonds, these stones are the hardest and also the most expensive option. That’s why diamond stones might not be the best option for everyday honing and sharpening. They are more suitable for occasional honing for extending the working life of your tools and can even be used to flatten Waterstones.

Grit Range

The grit range varies from 240 to 8000. A higher number indicates a finer grit. According to the Japanese grit guide the three grit grades are:

- Coarse grit (200-800), recommended for repairing chipped edges

- Medium grit (800-1500), recommended for sharpening dull edges

- Fine grit (1500+), recommended for refining and finishing an edge

You might want to try different stones in the beginning to see which ones work best for you. Basic stones have two sides, one side with fine and the other with rough grit. The higher the grit value, the less time it’ll take to sharpen a blade. Of course, a higher value also means it’ll shave off more metal– so you have to be careful when using high-grit stones.

Other Ways of Maintaining Cutting Tools

Whether you want to sharpen knives, saw blades, hedge trimmer, drills, or wood scissors–the right method is necessary for maintaining your cutting tools. For drill bits and saw blades, the sharpening method will thin the steel or carbide layer on the surface. Knife blades need their thread reformed, while other tools will need certain adjustment to get the best cutting edge. Other than using whetstones or grinding wheels yourself, we can also consider the following alternative solutions for keeping cutting tools sharp:

- Manual or electric sharpener: there are various models available on the market in each category; you can choose one according to your budget and needs

- A professional sharpening service: If you don’t want to take any risks, hiring a professional to sharpen your cutting tools is the best way. This will not just give you great results, but also extend the tool’s life

Sharpening your cutting tools is one of the most important safety practices when using power tools. The same goes for hand tools as well, so do have a tool-sharpening routine in place for your tool collection.

How to Maintain Cutting Tools

Along with knowing how to sharpen cutting tools, it’s also important to know how to maintain them. Without the proper maintenance, cutting tools will lose their sharpness more easily and may also get damaged more quickly than usual.

So, what strategies should we adopt in order to make the most of our cutting tools? The tips below should help in achieving this goal, along with limiting the maintenance and replacement costs for such tools.

1. Control the Temperature

Heat can adversely affect the life of your cutting tools. The cutting process of metal cutting tools especially can create a lot of heat. This will wear out the tips and surfaces of such tools.

We can limit the damage of this heat by using oil or some other recommended lubricant when using a powerful cutting tool. These agents will do away with friction, preventing the deterioration of your tools.

2. Preparing the Edges and Controlling Chips

When you prepare the edge of a tool you’re removing material from its side. This practice extends tool life by strengthening the edges and also disposing of the weak side of its material. This also prevents edge chipping and balances the toughness of the tools.

3. Coating Inserts

We should apply a coating to metal cutting tools according to their unique design. This prevents extreme heating, with the most popular types of coating being Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD). The latter is thicker, while the former is thinner and preferable for tools with very sharp edges.

Whether you’re sharpening chainsaws or some other cutting tools, proper care is important for extending their lifespan. Here are some other general tips for maintaining your cutting tools:

- Make sure the tools are stored in a dry, coo, and secure area

- When possible, store the tools in their original packaging–otherwise, invest in a storage rack or at least a sturdy plastic box

- Put some silica gel packs or rust collectors in the storage area

- Clean the tools after every use; any remaining moisture or debris can lead to corrosion

- Inspect the stored tools regularly for signs of damage or wear and tear

- Maintain the tool batteries, if any, and replace or remove them as needed

- Sharpen the tools as soon as you notice any sign of dullness

- Try storing the cutting edge in a piece of foam

- If allowed by the manufacturer, put some machine oil on cutting tools for extra protection.

Conclusion

Keeping your cutting tools sharp is essential if you want to stay safe and efficient while working on various projects. Whether it’s gardening, woodworking, crafting, or some other task, cutting tools are sure to be part of your arsenal.

Need more details on how to go about maintaining your cutting tools? An introduction to sharpening tools might be in order.