If you are an enthusiastic DIYer, you’ll know how important it is to sand different surfaces. Proper sanding ensures an excellent finish whether you are working with wood, drywall or even metal. Sanding the edges and surfaces after cutting, before applying a finish, and in between paint coats makes the end result more appealing and aesthetically pleasing.

When you start working on a new project, the first thing you do is gather supplies. Checking off sandpaper from the list of tools and materials may seem very easy, but things get a little complicated when you reach the hardware store. The stack of sheets and booklets, each distinctly identified by different numbers can make buyers wonder what exactly they should buy.

This guide will walk you through important aspects of buying sandpaper by covering everything from sandpaper materials, to its grits, and applications.

Sandpaper Applications

Sandpapers are versatile and can be used with a power tool or simply by sanding the rough surface by hand.

Power Sanding

Power sanding tools remove the material from the surface very quickly and efficiently. They are a good choice when you are removing blemishes, or leveling or shaping a wooden surface. You can also use this equipment to prep different surfaces before painting over them.

Sandpaper for power sanding equipment is supplied as dedicated discs, belts, and sheets. Some tools also accept sheets that are cut to the right size.

Hand Sanding

Hand sanding works on surfaces where you want to give a lighter touch. When you sand by hand, you have better control on how much material you remove. This sanding technique is suitable for woodworking and finishing. When done correctly, the scratches will align with the wood grain, hence are less visible.

Sandpaper for hand sanding is sold as sheets that you can cut to size according to your own requirements.

Sandpaper Grit Numbers

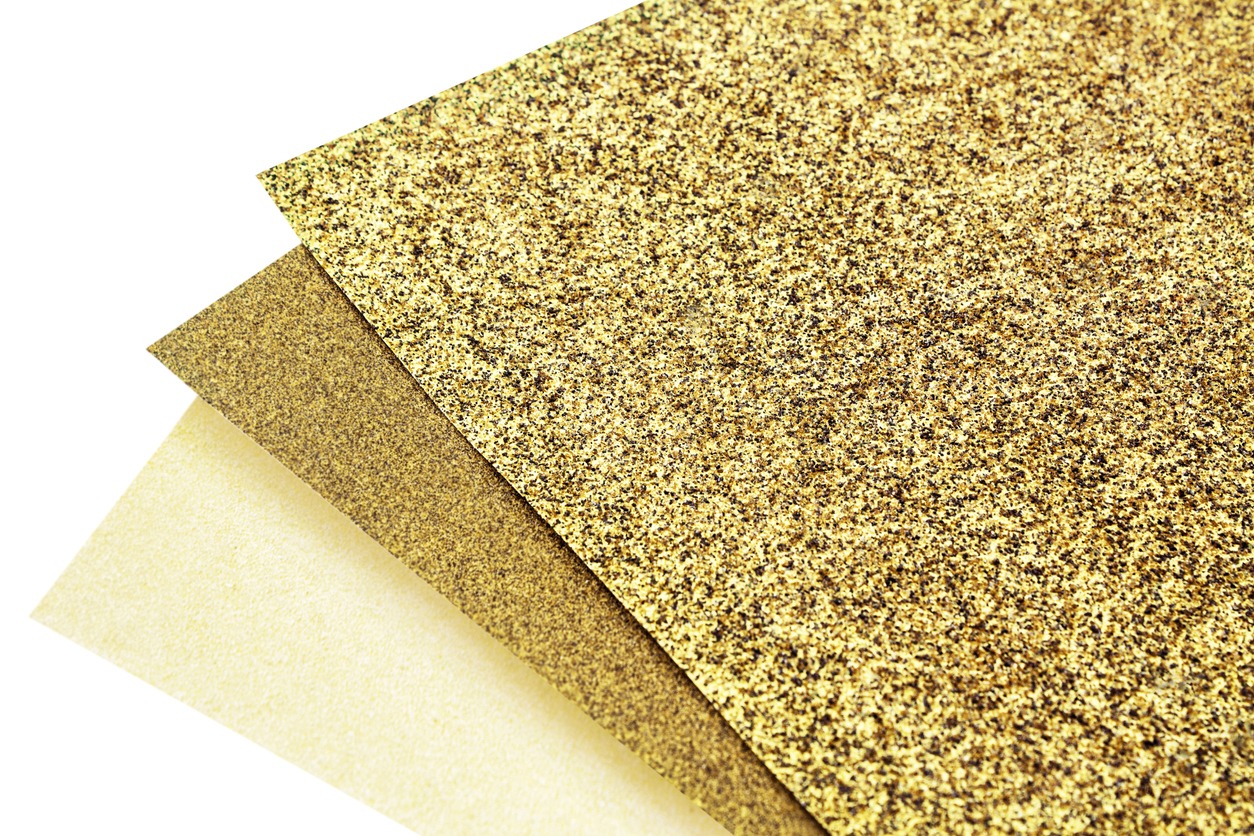

Sandpaper is named so because one of its sides is coated in crushed materials for abrasive purposes. The size of abrasive particles coating its sanding surface is what determines the grit of the sandpaper.

When the abrasive material is crushed, its grains (or grit) are sifted through different screens and sorted according to size before they are glued to the backing material.

Sandpapers are assigned different grit numbers according to the size of their abrasive particles. The grit numbers range from 24 to 2,000, with the smaller numbers for removing heavy materials and the higher numbers for doing fine finishing. In other words, the higher the grit number, the smoother the finish will be.

Grit numbers from 80 to 220 are suitable for most household projects. But the grit number that you want varies from one project to another, so it’s best that you follow the directions and get the grit number that the list calls for.

Here are general guidelines regarding sandpaper grit numbers:

Grit Numbers 24 to 100

These grit numbers form the extra coarse to medium coarse category of sandpapers. They are good at removing material, so choose them when you are leveling wood, shaping it, removing its flaws, or are stripping away finishes such as paint or varnish. These sandpapers are also effective at removing rust on metals, and also work well with power tools.

Grit Numbers 100 to 180

Sandpapers that fall in this category belong to the fine sandpaper category. These work well for both hand sanding and power sanding. You can use them to smoothen your workpiece, prepare a bare surface for finish, as well as for removing scratches.

Grit Numbers 180 to 320

These grit numbers make up the extra-fine category of sandpapers. Choose these when you plan on hand sanding. They work well for finishing purposes, such as smoothing raised wood fibers or scuffing between finish coats. Anything above 320 is super-fine/ultra-fine and used for achieving a smooth final finish.

Sandpaper Abrasive Grains

The success of your sanding project greatly depends upon the density of sandpaper and the type of abrasive grains. While most manufacturers clearly mention the abrasive material coating their sandpaper, sometimes it is not clearly mentioned. Knowing about the different sandpaper grains will help you out in such instances. Following are the main materials you’ll find on a sandpaper:

- Flint is a natural grain used to sand off surface materials such as old paints and varnish. It is well suited for this kind of job.

-

- Emery is another natural grain used in removing corrosion and polishing steel and other such substances. It is not suitable for doing woodwork as it has sharp edges.

- Garnet is a natural grain that is softer than flint and emery. So, it will quickly get dull when used on metal. It is suitable for fine sanding of wood.

- Zirconia Alumina is a synthetic grit. It is best for grinding the burrs on metal. You can also use it for the initial sanding of wood. It is long-lasting as the grit particles become sharper when used on metal.

- Silicon Carbide is the most durable synthetic grid. It can sand a wide range of materials such as hard and softwood, metal, and plastics.

- Screenback Abrasive is an innovative mesh network coated with high performance abrasive grains. It is ideal for stripping or sanding plaster surfaces because it reduces clogging. Plus, you can use both sides for longer service time.

Sandpaper Backing Materials

When buying sandpaper, you can choose between cloth and paper backing material. Your choice depends upon how flexible or resistant to tearing you want the tool to be.

- Paper backed sandpapers are the right choice for jobs that require flexibility. However, they are prone to tearing so choose an option with thicker and stronger paper backing.

- Cloth makes a sandpaper durable and more resistant to tearing. Cloth backed sandpaper can tolerate regular bending and flexing during use. They are great for dry sanding tasks that involve removing heavy material. You can also cut these into thin strips and use them for sanding contours, such as stair spindles.

Different Sanding Tools

While sandpaper is a versatile tool in itself, you can pair it with a variety of tools to get the job done more quickly and efficiently. There are many tools that you can use for both hand sanding and power sanding. The commonly used tools include:

- Manual hand sanders are inexpensive tools often made from rubber. They feature a pad and side clamps to hold the sandpaper. They also have a handle that you can hold to move the abrasive surface quickly and easily. They are a great choice when you want to sand a large area that would take much longer to do by hand.

- Sanding Blocks are often crafted from a flexible sponge coated with sanding material. Bring supple, this sanding tool allows you to uniformly sand rounded edges by simply keeping it pressed against the edge as you sand.

- Vibrating Palm Sanders are corded power tools small enough to fit in your palm. This tool comes with various sanding plate shapes, including triangular for hard to reach areas and rectangular for working on open surfaces.

- Orbital Sanders move in a calculated circuit pattern that you can consider as spinning. You can use these with pre-cut sanding pads or with cut pieces of a regular sandpaper sheet, depending upon its size and brand.

- Random Orbital Sanders move both in circular and in an arbitrary side-to-side and back-and-forth pattern to prevent visible sanding marks.

- Belt Sanders are powerful handheld sanding tools but require both hands for operation. They are used with pre-packaging sanding belts.

- Drum Sanders feature a large cylinder fitted with a wide sanding belt or loop. They are quite aggressive, and should be used carefully.

- Bench Mounted Sanders mount permanently on your workbench and are useful for small woodworking projects. When using these, you move the work surface against the sander.

- Floor Sanders either have large cylinders, belts, or oscillating plates. These powerful machines make quick work of sanding wooden floors.

In a Nutshell

Sanding is an essential step in woodworking and finishing projects. Sandpapers are available in various grit numbers, abrasive grains, and backing materials, so you should carefully check the type you need before purchasing. You can choose to sand by hand or use a tool for power sanding. Power sanding is an efficient way of removing heavy material in a short time, and you have a variety of tools to complete your desired job.