Air compressors are useful devices that provide compressed air to numerous tools and machines. These air compressors are often utilized in factories, workshops, and construction sites, where they are effective in supplying pressurized air to pneumatic tools like paint sprayers, jackhammers, engines, pavement breakers, and rock drills.

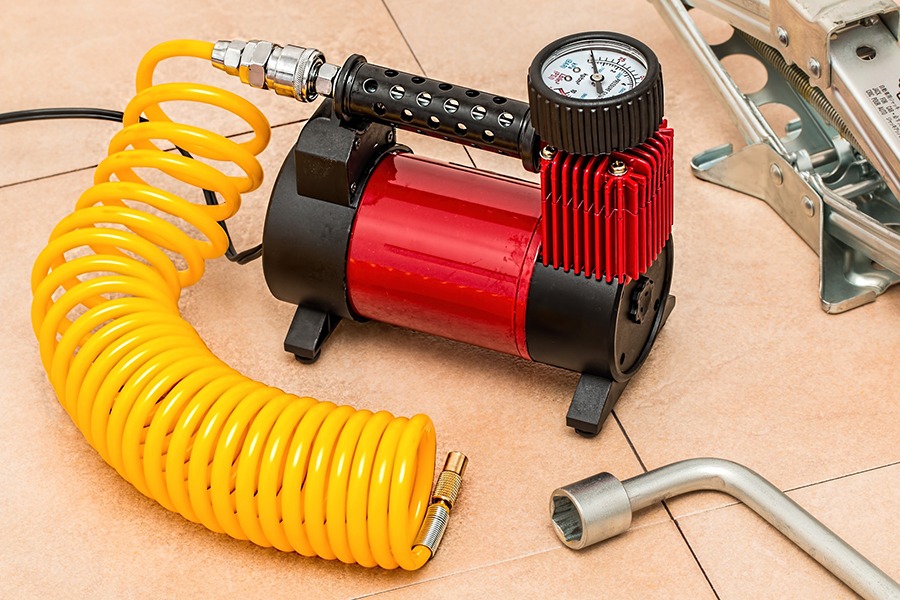

In addition to industrial purposes, air compressors can also be used at home, although the size of these devices is much smaller compared to the ones used in factories. The air compressor at home can be utilized to inflate balls for different sports, inflatable pools, and tires. Because of how popular and useful air compressors are today, there are already hundreds of them to choose from, and most of those are readily available for purchase in online shops and physical DIY stores.

Before buying an air compressor, there are two questions that should be asked: “What is an air compressor?” and “what are its uses?” By learning more about air compressors, you will have an easier time deciding if you really need one at home or for your business. To get the answers to the questions we mentioned, let us dive right into the guide to air compressors and how to look for the most suitable one for your needs.

What is an Air Compressor?

An air compressor is a machine that collects air from its environment and compresses it to create pressured air. However, in order for it to compress or pressurize air, it needs power, which it can get from a gasoline engine, diesel engine, or an electric motor that connects to one of your house’s power outlets. When it has enough power, it would then collect air from its surroundings and would force more and more air into its built-in storage tank until the air compresses. If the pressure inside the tank has already reached the upper limit, the air compressor automatically shuts off, but it would still retain the pressurized air. [1]

The pressurized air from the air compressor can then be used for various applications, and these include applying air to pneumatic tools like jackhammers, providing air to gas cylinders, adding air to tires, and filling the much larger high-pressure air tanks.

What are the Classifications for Air Compressors?

Air compressors today are divided into two classifications and different types. The classifications for air compressors are established based on how the devices are able to collect and compress air. Take a look below for details about the two classifications of air compressors.

1. Positive Displacement Compressors

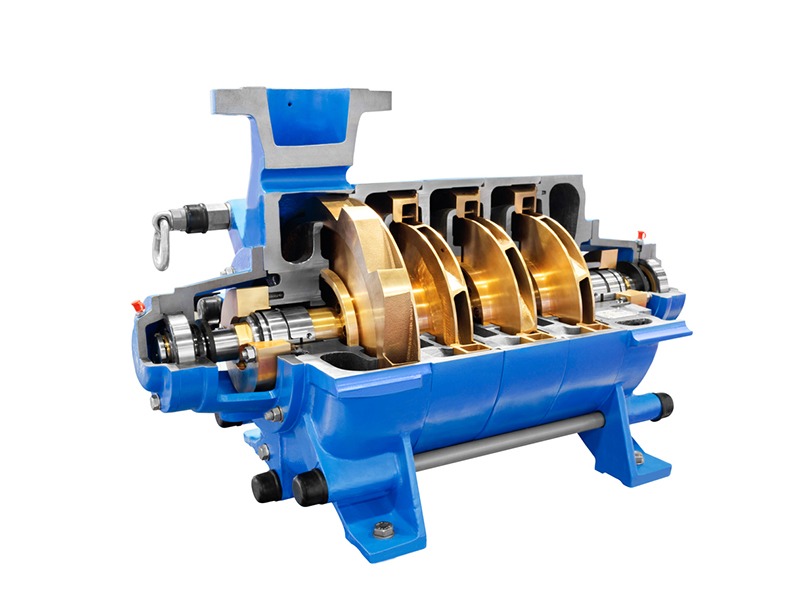

Positive displacement compressors are devices or machines that collect a specific amount of air in the environment and trap it in a compression chamber or cylinder. The area occupied by the area will then slowly be reduced until the air compresses due to not having enough space to move within the chamber or cylinder. These positive displacement compressors are often found in homes and small factories or workshops. [2]

2. Dynamic Compressors

Dynamic compressors are large air compressors that are more suitable for industrial use. Manufacturing facilities, large factories, and production plants are typically the ones that use dynamic compressors, and because of the large size and complex mechanisms of these devices, they wouldn’t really recommend them for home use.

The air on these large compressors continuously flows into the cylinders and is always under constant pressure, unlike the positive displacement compressors, where pressure will only be applied once a certain amount of air is already collected in the machine’s cylinder or chamber. [2]

What are the Different Types of Air Compressors?

There are various types of air compressors that are available for businesses and ordinary people to buy, and each of these types has its own way of collecting and compressing them to pressurized air. Here are some of the most popular types of air compressors today.

1. Rotary Screw Compressor

One of the most common types of air compressors is the rotary screw compressor, which is a large device that has two rotors inside it that turn in opposite directions. These rotors are responsible for producing compressed air. As the rotors rotate, they will build pressure that would then compress the air placed between them. [3]

In order for the rotors and the motor that is controlling them to not overheat, the rotary screw compressor has an internal cooling system to keep the temperature tame inside the device. Almost all of the most available air compressors that you can get are rotary screw compressors, as they are relatively affordable to produce and sell compared to other types of compressors.

2. Reciprocating Compressor

Another common air compressor type is the reciprocating compressor, which has a piston that would pressurize air trapped inside a metal cylinder. While the rotary screw has a very simple design, the reciprocating compressor’s design is much more complex and involves more moving parts, which is why it is much more susceptible to damage compared to the other mentioned compressor. In addition, reciprocating compressors are also more susceptible to overheating, so it is not suitable for continuous use.

However, what’s great about the reciprocating compressor is that they tend to have better quality compressed air compared to the rotary screw compressor, so they are great to use for tools or appliances that require clean air. There are two sub-types of air compressors, which are single-stage and multi-stage. Single-stage compressors are usually smaller and are more suitable for home use or for small workshops, but for factories or small construction plans and projects, the bigger multi-stage compressor is more suitable.

3. Centrifugal Compressor

Centrifugal air compressors are typically high-grade compressors that are used in factories and manufacturing plants. However, these compressors are smaller compared to other industrial compressors, although it is still able to produce high amounts of compressed air. The centrifugal compressor slows down and cools the air that flows through the diffuser, and this air would then be compressed to create energy. [3]

4. Axial Compressor

Axial compressors are gigantic air compressions that are more suitable for wide-scale projects that need a lot of compressed or pressurized air. Because of how big and complex axial compressors are, they are usually much more expensive compared to other types of compressors. The axial compressor has a high efficiency rate, which basically means that it rarely fails and is reliable when it comes to providing plenty of compressed air. This type of compressor is often found in high-speed engines for airplanes and ships.

What are the Uses of Air Compressors?

The different types of air compressors would also have various uses or purposes. What’s interesting about air compressors is that they are incredibly versatile, as they have more utilization compared to most tools and devices. To know more, here are pieces of information about the different uses of air compressors.

1. Inflating Objects

For home use, air compressors are effective in inflating various objects, which include air mattresses, balloons, car tires, and sports balls. People have the option of just using air pumps for those inflatable objects, but air pumps are slower in blowing air, and it also requires more effort from the user since he or she has to pump the handle at the top of the device manually.

With air compressors, you can just automatically inflate tires, balls, and balloons after a press of a button or switch. But be careful not to overinflate objects since some compressors don’t have an auto-shutoff function.

2. Scuba Diving

Air compressors give air to pressurized air tanks, which are then used for scuba diving. These pressurized air tanks allow divers to continue diving underwater for longer periods of time. Scuba diving is usually performed as a hobby, but there are also divers that participate in rescue or search and retrieval missions, and they require more pressurized air for intensive searches and rescues.

3. Spray Painting

Spray painting is arguably the fastest way to add color to different objects, and this type of painting is only possible through the use of pressurized air supplied by air compressors. There are many different sizes of airbrushes available in the market, with some small enough to paint shoes and action figures, while others are big enough to paint walls, tiles, roofs, and car exteriors.

Besides sizes, airbrushes are also available in different types, which are categorized by how they store paint before spraying. The three main types of airbrushes are gravity brush, siphon feed brush, and side feed brush. [4] All of these types of airbrushes require compressed air to work.

- The gravity brush has a paint cup on top of it, and then the paint would drip down to the interior of the brush and would come into contact with compressed air.

- The siphon feed brush has a detachable bottle that connects to the bottom of the brush. The compressed air would then pull up or siphon the paint inside the bottle whenever you activate the airbrush.

- The side feed brush is a mix of the two previous types, as it can use either a gravity cup or a siphon bottle, and the storage compartment for the paint is installed to the side of the brush.

4. Pressure Washing

Cleaning tiles, floors, walls, and different pieces of furniture that are very dirty can be difficult to do if you are just using regular cleaning tools. But with the help of pressure cleaners and water blasters, you can clean almost anything thoroughly in less than an hour. The water blaster and pressure cleaners are able to produce high-pressure water with air compressors, which contain compressed air that is needed to make the water have more force and pressure to push out dirt, stains, and grime. [5]

5. Construction

One of the most popular uses of air compressors is for constructions, as the compressors are utilized to supply much-needed power and strength from different pneumatic tools, such as jackhammers, drills, chipping hammers, nail guns, and more. Most of the air compressors used in construction sites are reciprocating compressors that are relatively larger in size compared to the ones used for homes.

6. Woodworking or Carpentry

Woodworking or carpentry is pretty much related to construction, as some of the tools needed for woodworking are also used in construction sites, like nail guns and drills. However, woodworkers also use air compressors for sanding, which allows them to prepare wooden surfaces for treatment and eliminate uneven areas and dirt from the wood. The air compressor also offers power to blow guns, which are utilized in woodworking to clean wooden slabs or sheets efficiently. [6]

7. Manufacturing

Some of the largest machines in manufacturing plants or factories need compressed air for extra power, which is why air compressors are always present in those areas or establishments. Two of the machines or pieces of equipment that need air compressors are conveyor belts and heat press machines.

8. Agriculture

In the agriculture industry, air compressors are primarily used to provide compressed or pressurized air on water pumps, crop conveyors, and tractors, which are machines or devices that help farmers have a much easier time collecting or harvesting crops. The air compressors also supply clean air to dairy farms and greenhouses.

9. Heating and Ventilation

Speaking of providing clean air, air compressors are also widely used for heating and ventilation, as they are a cleaner and safer way to control clean air and make them warmer or colder. The air compressors are connected to air condition units, which are responsible for controlling the temperature of the air pumped out by the compressors. For vehicles, aircraft, and sea vessels, air compressors are also utilized for heating and cooling different engines. [7]

10. Medical Purposes

There are medical air compressors that are utilized to provide clean air in wards and operating rooms to prevent infection from various viruses or bacteria. In addition, air compressors are also utilized to deliver oxygen tanks to patients. In terms of dentistry, air compressors are used on pneumatic tools that are needed by dentists to perform teeth cleaning, teeth extraction, and other types of dental procedures.

How to Choose the Right Air Compressor

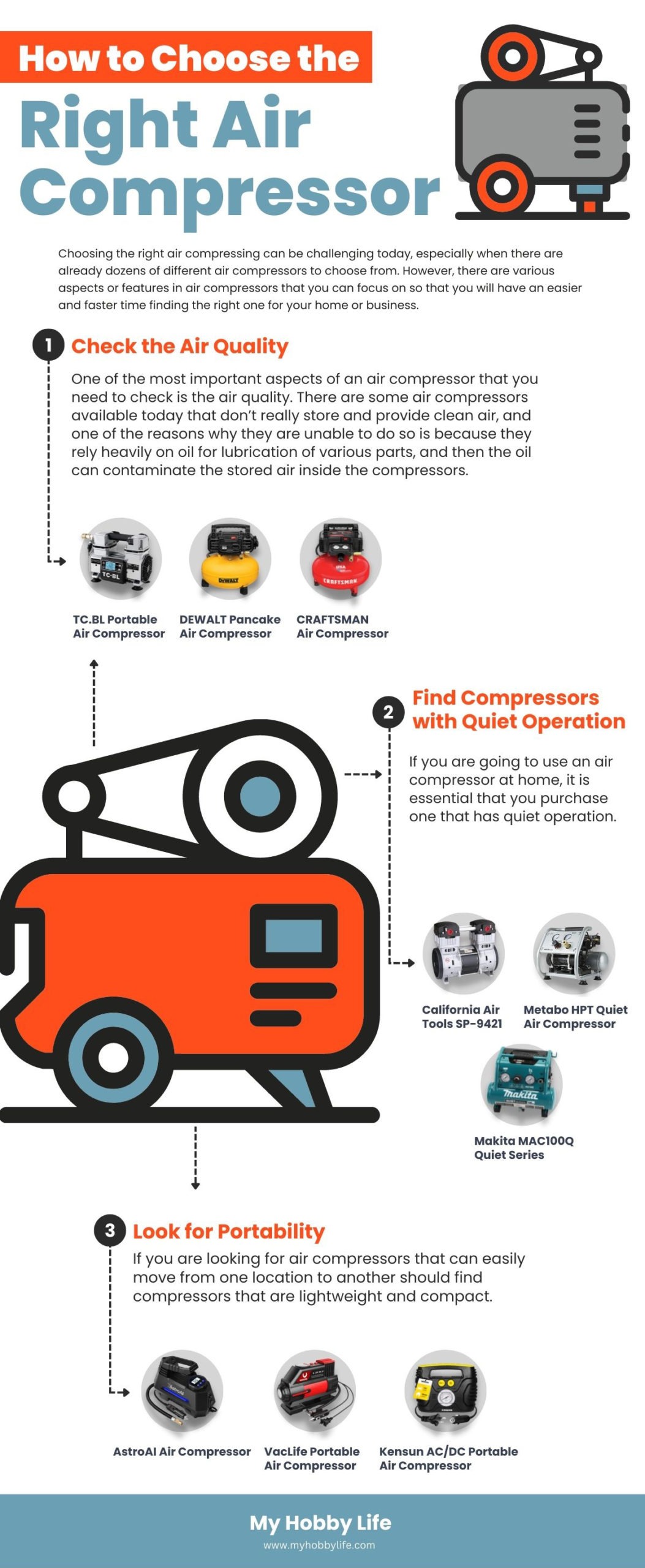

Choosing the right air compressing can be challenging today, especially when there are already dozens of different air compressors to choose from. However, there are various aspects or features in air compressors that you can focus on so that you will have an easier and faster time finding the right one for your home or business. Here are the tips for choosing the right air compressor.

1. Check the Air Quality

One of the most important aspects of an air compressor that you need to check is the air quality. There are some air compressors available today that don’t really store and provide clean air, and one of the reasons why they are unable to do so is because they rely heavily on oil for lubrication of various parts, and then the oil can contaminate the stored air inside the compressors. The contaminated air would often damage pneumatic tools, as well as devices or machines that are connected to the air compressor.

If you don’t want the hassle of checking whether that lubricating oil you applied has contaminated the compressed air, you can just go for oil-free compressors, which have moving parts that don’t need to be oiled regularly for them to move and work smoothly and consistently. Here are a few oil-free compressors we recommend.

- TC.BL Portable Air Compressor – the TC.BL Portable Air Compressor is a small machine that is suitable for home use or for providing compressed air for small workshops. What’s great about this particular air compressor is that it has an LCD screen and controller wherein you can easily set the pressure of the machine from 40 psi to 130 psi.

- DEWALT Pancake Air Compressor – one of the most popular air compressors on the market is the DEWALT Pancake Air Compressor, which is an oil-free machine that can work for hours and even days. The DEWALT compressor has a 6-gallon chamber that is sufficient for providing compressed air at home or in the garage.

- CRAFTSMAN Air Compressor – another pancake-style air compressor is the CRAFTSMAN compressor, which has a maximum pressure of 150 psi that is enough to offer energy to small or medium-sized pneumatic tools that you can use at home. Much like the DEWALT, the CRAFTSMAN compressor has a 6-gallon chamber that is durable and requires little to no maintenance.

2. Find Compressors with Quiet Operation

If you are going to use an air compressor at home, it is essential that you purchase one that has quiet operation, which basically means that it wouldn’t make any loud noises while it is activated. In the past decades, air compressors can be quite noisy, so most of them are not really suitable for home use, as their noise can be annoying at night when people are trying to sleep. Today, there are already plenty of options when it comes to noise-free and quiet air compressors. Here are a few we highly recommend.

- California Air Tools SP-9421 – this air compressor has an ultra-quiet operation that makes it one of the quietest air compressors on the market. This machine is also oil-free, so it doesn’t need regular maintenance and lubrication. Its 2-horsepower motor allows it to collect and pump out compressed air efficiently.

- Metabo HPT Quiet Air Compressor – the Metabo HPT air compressor is another machine with an ultra-quiet operation, as it operates at only 59 dB, which would not overpower conversations and sounds coming from a TV set. The Metabo HPT is also compact and easy to move from one place to another.

- Makita MAC100Q Quiet Series – besides being a very quiet air compressor that only produces about 58 dB of sound or noise, the Makita MAC100Q also has a complete roll-cage construction that offers more durability compared to most air compressor designs.

3. Look for Portability

If you are looking for air compressors that can easily move from one location to another should find compressors that are lightweight and compact. Portability is essential for home use, as you may often need compressed air in different areas of the house. Although a lot of portable air compressors are not suitable for pneumatic tools and devices, they are still quite useful for other small applications, like adding air to tires or mattresses. Check out these three portable and compact air compressors that are lightweight and reliable.

- AstroAI Air Compressor – one of the fastest tire and bed mattress inflators on the market is the AstroAI Air Compressor, a portable device that can fill up tires and mattresses in under 5 minutes. You can set the pressure of the air compressor by pressing the M button first on the devices and then pressing the + and – button to control how much pressure the compressor pumps out.

- VacLife Portable Air Compressor – in addition to being lightweight and portable, the VacLife air compressor also has an auto-shutoff function so that you won’t accidentally overfill a tire, bed mattress, or basketball. You can also use this air compressor even at night or in the dark, as it has an LED display that will show you the target pressure of the compressor as well as the real-time pressure of the object you are applying air to.

- Kensun AC/DC Portable Air Compressor – this compact and lightweight air compressor is what you will need for your car, as it is reliable enough to provide proper pressurized air into the tires of your vehicle while also being light and small enough to fit in large glove boxes or car compartments. Besides tires, it can also be used to inflate balls, plastic pools, and inflatable toys.

Conclusion

These are the things that you need to know about air compressors, their types, and how to find the best one for your home, car, or workshop. If you aren’t sure which model or brand of air compressor to buy, it would be a great idea to read or watch reviews of popular and new air compressors, as they will give you important information about each compressor’s pros and cons, as well as their features and functions.

References

[1] Sabhadiya, J. (2021, October 1). What is Air Compressor? – Definition, Types and Working. Engineering Choice. Retrieved September 26, 2022, from https://www.engineeringchoice.com/what-is-air-compressor/

[2] Natural Resources Canada. (2015, December 14). Air Compressor Types and Controls. Natural Resources Canada. Retrieved September 26, 2022, from https://www.nrcan.gc.ca/energy-efficiency/energy-star-canada/about/energy-star-announcements/publications/energy-efficiency-reference-guide-compressed-air/air-compressor-types-and-controls/14970

[3] BigRentz. (2022, June 15). 4 Types of Air Compressors: Which is Right for Your Project? Big Rentz. Retrieved September 26, 2022, from https://www.bigrentz.com/blog/air-compressor-types

[4] SprayGunner. (2016, November 12). Types of Airbrushes. things to know when buying first airbrush. Spray Gunner – Painter’s Arsenal. Retrieved September 27, 2022, from https://spraygunner.com/blog/types-of-airbrushes-buying-first-airbrush/

[5] Coates. (2019, January 15). 13 Uses For Air Compressors. Coates.com.au. Retrieved September 27, 2022, from https://www.coates.com.au/13-uses-for-air-compressors

[6] Quincy Compressor. (2021, October 26). Applications of Air Compressors for Personal and Professional Use. Quincy Compressor. Retrieved September 27, 2022, from https://www.quincycompressor.com/applications-of-air-compressors/

[7] ISeekPlant. (2020, June 15). Top 10 Uses of Air Compressors. ISeekPlant. Retrieved September 27, 2022, from https://blog.iseekplant.com.au/blog/top-ten-uses-air-compressors